In today’s manufacturing, automotive, and electronics industries, laser cutting machines have become indispensable tools for precision cutting, engraving, and shaping materials. Whether you’re a hobbyist, small business owner, or industrial manufacturer, selecting the right laser cutting machine is critical to achieving optimal results, maximizing efficiency, and ensuring long-term value. With a wide range of options available, it’s essential to consider key factors that align with your specific needs. In this guide, we’ll break down the most important considerations when choosing a laser cutting machine, from material compatibility to brand reliability.

1. Material Type and Thickness: Match the Machine to Your Workpiece

The first step in choosing a laser cutting machine is understanding the materials you’ll be working with and their thicknesses. Different laser technologies are engineered to interact with specific materials, and using the wrong type can lead to poor results, machine damage, or safety hazards.

CO₂ Lasers: Ideal for non-metal materials such as wood, fabric, paper, acrylic, and plastics. Their wavelength (10.6 μm) is absorbed efficiently by organic materials, making them perfect for detailed engraving or cutting thin to medium-thickness non-metals.

Fiber Lasers: Designed for metal cutting, including steel, aluminum, brass, and copper. With a shorter wavelength (1.06 μm), fiber lasers deliver high energy density, enabling precise cuts on thick metal sheets—often up to 30mm or more, depending on power.

Other Specialized Lasers: For unique materials like glass or ceramics, consider ultrafast lasers or green lasers, which minimize heat-affected zones (HAZ) and reduce material stress.

Example: If your projects involve cutting 10mm stainless steel sheets, a fiber laser machine is non-negotiable. For acrylic signage or wooden crafts, a CO₂ laser would be more cost-effective and efficient.

2. Laser Power: Balance Power with Application Needs

Laser power directly impacts a machine’s ability to cut through materials—higher power means thicker materials can be processed. The right power level depends on your typical workpiece thickness and production volume:

Entry-Level (40–100 Watts): Suitable for hobbyists or small businesses working with thin materials (e.g., 1–3mm acrylic, fabric, or paper). These machines are compact, affordable, and easy to operate.

Mid-Range (100–500 Watts): Ideal for medium-duty tasks, such as cutting 3–10mm metals (aluminum, mild steel) or thicker non-metals (6–12mm acrylic).

Industrial-Grade (1,000+ Watts): Designed for heavy-duty manufacturing, capable of cutting 10–30mm+ metals (stainless steel, carbon steel) at high speeds. These machines often feature advanced cooling systems and automation integration.

Key Tip: Avoid overbuying power if you only work with thin materials—unnecessary wattage increases energy costs and machine size. Conversely, underpowered machines will struggle with thick materials, leading to slow production and inconsistent cuts.

3. Bed Size: Ensure Sufficient Working Area

The bed size (or working area) of a laser cutting machine determines the maximum dimensions of material it can process. It’s critical to match the bed size to your project requirements:

Small Bed (600×400mm or smaller): Perfect for small-scale projects like jewelry, phone cases, or custom decals. These machines are space-saving and portable.

Medium Bed (1300×900mm to 1500×3000mm): Suitable for larger sheets, such as signage, furniture components, or metal panels.

Large Bed (3000×1500mm+): Reserved for industrial applications, such as automotive parts or architectural metalwork, where full-size sheets need processing.

Consider Future Growth: If you anticipate scaling operations, invest in a slightly larger bed size to avoid outgrowing your machine prematurely.

4. Budget: Account for Upfront and Long-Term Costs

Laser cutting machines vary widely in price, from $500–$5,000 for hobbyist models to $50,000–$500,000+ for industrial systems. When setting a budget, look beyond the upfront cost:

Initial Investment: Includes the machine, software, and essential accessories (e.g., fume extractors, rotary attachments for cylindrical objects).

Operating Costs: Energy consumption (higher power = higher electricity bills), replacement parts (laser tubes, lenses), and maintenance (cleaning, calibration).

ROI Timeline: Industrial machines may have higher upfront costs but deliver faster production speeds and durability, reducing long-term per-unit costs.

Pro Tip: Prioritize reliability over the lowest price. A cheap machine with frequent breakdowns will cost more in repairs and downtime than a mid-range, durable option.

5. Brand Reputation and Reviews: Trust Quality and Support

A brand’s reputation is a reflection of its product quality, customer service, and reliability. Before purchasing:

Read Reviews: Check industry forums, Google Reviews, and social media for feedback on machine performance, ease of use, and after-sales support.

Evaluate Customer Service: Look for brands offering responsive technical support, warranty coverage (1–3 years is standard), and training resources.

Assess Track Record: Established brands with years of experience (e.g., 10+ years in the industry) are more likely to have refined their technology and support systems.

Red Flag: Avoid brands with little to no online presence or vague warranty terms—these often indicate poor quality or limited support.

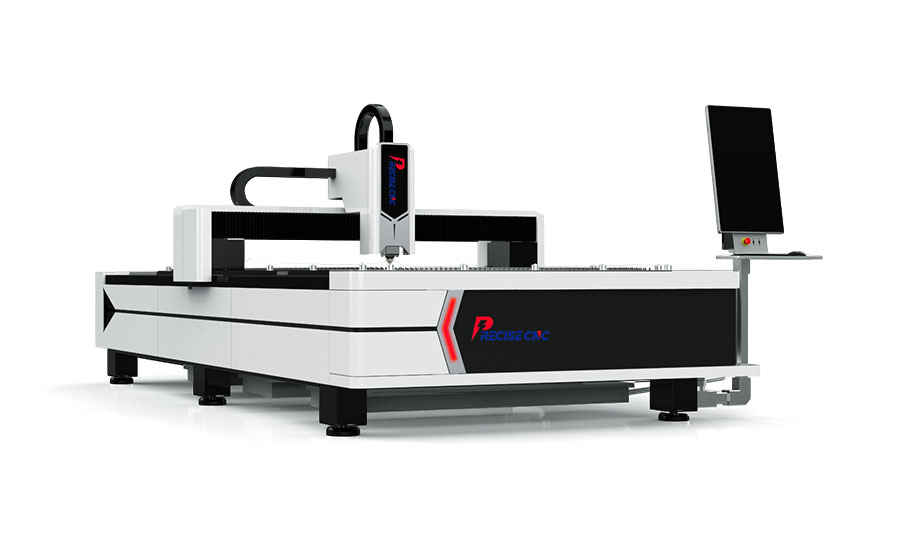

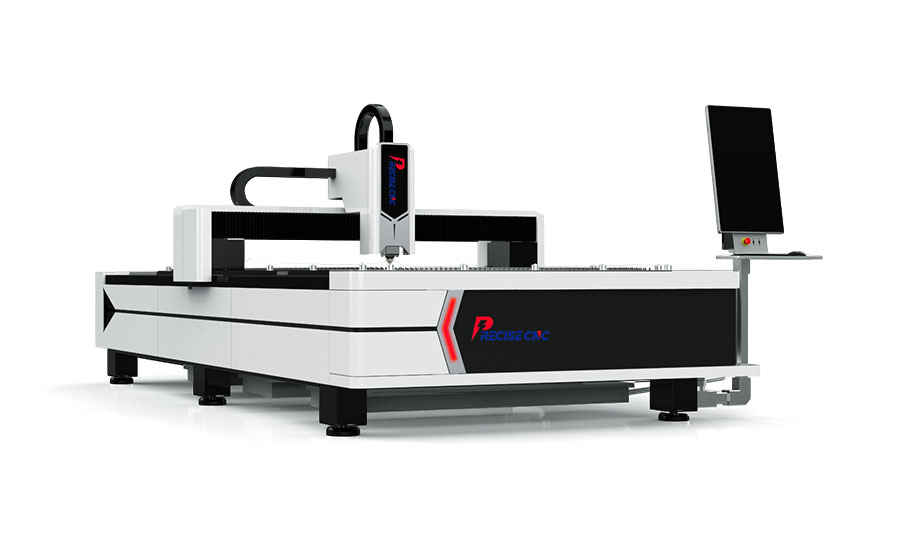

Why Choose Precise CNC’s Laser Cutting Machines?

When it comes to reliable, high-performance laser cutting solutions, Jinan Precise CNC Equipment Co., Ltd stands out as a global leader. With over 13 years of experience (founded in 2010), we specialize in ultra-fast laser precision processing, serving industries from automotive and 3C electronics to photovoltaic and medical manufacturing. Here’s why our machines are trusted by businesses in 100+ countries:

✅ Comprehensive Product Range for Every Need

Our product lineup covers all material and application requirements:

Sheet Metal, Tube, and Sheet-Tube Combined Laser Cutters: Ideal for metal fabrication, with options for thin to thick metals (up to 30mm+).

CO₂ and Fiber Laser Solutions: Non-metal cutting (acrylic, wood) and high-power metal cutting, respectively.

Specialized Machines: Glass laser cutting/drilling machines, robot laser cutting systems, and ultrafast lasers for precision micro-processing.

✅ Uncompromising Quality

Every machine undergoes strict quality control and rigorous testing before leaving our 20,000㎡ factory. We use premium components (e.g., imported laser sources, servo motors) to ensure durability and consistent performance.

✅ Global Support and Service

24/7 Online Support: Our team is available to resolve issues promptly, minimizing downtime.

Free Annual Factory Training: Visit our facility for hands-on learning and machine maintenance workshops.

Priority Order Processing: Agents and bulk buyers enjoy faster delivery times, ensuring your production stays on schedule.

✅ Industry-Specific Expertise

We tailor solutions to your sector. Whether you need high-speed cutting for automotive parts or precision drilling for medical devices, our R&D team works closely with you to optimize machine settings for your unique workflow.

Ready to Find Your Perfect Laser Cutting Machine?

Choosing the right laser cutting machine requires balancing material needs, power, budget, and brand reliability. At Precise CNC, we’re committed to delivering solutions that grow with your business—backed by quality, service, and decades of expertise.

Explore our full product range at www.precisecnctec.com/products.html or contact our team at www.precisecnctec.com/contactus.html to discuss your requirements. Let’s build a cutting-edge solution together.