Product Name: Infrared Picosecond Glass Laser Drilling Machine

Model: PR-RLD120,PR-RLD180,PR-RLD250

Laser Power: 120w/180w/250w

Application: Consumer Electronics,Home Appliance Glass,Architectural Decorative Glass,Automotive Glass,Optical & Solar Glass

Inquire

General Introduction

The Infrared Picosecond Glass Laser Drilling Machine is a high-precision solution designed for fast, clean, and crack-free drilling of ultra-thin and hard glass materials. Utilizing ultrashort picosecond pulses at infrared wavelengths, it minimizes heat-affected zones, ensuring smooth edges and superior hole quality. Ideal for applications in display panels, touchscreens, camera lenses, and other high-tech glass components, this machine offers exceptional stability, micron-level accuracy, and efficient performance for both R&D and mass production environments.

Product Specification

| Model No. | PR-RLD120 PR-RLD180 PR-RLD250 |

| Laser type | Infrared picosecond laser |

| Laser power | 120w/180w/250w |

| Wave length | Infrared picosecond laser 1064nm |

| Pulse Frequency | 1Hz - 1000kHz |

| Pulse width | 2~50ns |

| Pulse length | <10ps |

| Maximum hole size | 80*80mm 2mm diameter minimum |

| Chip edges | 300/500μm |

| Cooling mode | Water cooling |

| Brand name | PRECISE CNC |

| Laser drilling head | Bessel |

| Acceleration | 1G |

| Linear Speed | Up to 1000mm/s |

| Average edge collapse | <350um |

| Spot diameter | 0.6±0.2mm |

| Processing speed | 0-2000mm/s |

| Platform repeated positioning accuracy | ± 2μm |

| Platform dynamic positioning accuracy | ± 5μm |

| Camera positioning accuracy | ± 0.01mm |

| Applicable materials | Ultra-white glass, ordinary white glass, Borosilicate glass, Optical glass, Quartz glass,lstained glass, laminated and coated glass, sapphire glass, mobile phone panel, camera glass cover,k9 glass, LCD screen, etc. |

| Power Requirement | 220V 1PH 50/60HZ |

| Machine weight | About 3000kgs |

Glass Laser Drilling Machine Main Configurations

| Visual alignment system | ||

| Camera | 5000k CCD | |

| Light source | Ring-shaped adjustable brightness light source | |

| Positioning | Recognize Mark for automatic alignment | |

| Accuracy | ≤±3μm | |

| software copyright | PRECISE CNC | |

| File Format | Dxf, dwg | |

| Motion control card | High-precision motion control card (including PSO laser control) | |

| PC(Computer) | Industrial control computer, motherboard imported from Taiwan | |

| Display | 19 "AOC LCD display | |

| Keyboard mouse | Wireless | |

| Hardware configuration system | ||

| Low-voltage electrical components | Schneider, France | |

| Switching power supply | MeanWell | |

| Smoke exhaust system | 550w centrifugal fan | |

| Power-off protection system | PC side UPS uninterruptible power supply | |

| Standard accessories | ||

| Tool kit | A set (including lens cleaning agent, daily tools, etc.) | |

| Operating manual | One set of electronic and one set of paper versions | |

| Chiller Maintenance Manual | One set of electronic and one set of paper versions | |

| Warranty card/certificate of conformity | 1 set | |

| Cartographic software | In addition to the device itself, it can also be installed on an office computer | |

Sheet Metal Laser Cutting Machine Features and Advantages

Glass Laser Drilling Machine Video

Main Advantages Features

Incorporating multiple functions into one to creates more value for customers.

Advanced Design and Construction

Features a fully enclosed, integrated structure with a modern and streamlined appearance.

Built on a marble or granite base, incorporating a gantry and column architecture to ensure structural stability.

Ergonomic and User-Friendly Interface

Equipped with a human-centric workstation layout designed to enhance operator comfort and usability.

Incorporates a user-friendly human-machine interface for efficient operation.

Precision and drilling Technology

Utilizes a side-axis CCD camera-assisted positioning system to ensure high accuracy in workpiece alignment.

Integrated linear motor system supports high-speed drilling, significantly increasing processing efficiency.

Laser Head and Processing Capabilities

Features a customized laser drilling head with a positive pressure sealing device to protect internal components from environmental exposure and extend service life.

Enables non-contact processing, avoiding mechanical stress and allowing precise drilling of complex geometries and micro holes.

Range of Application

Drilling of non-strengthened glass, such as smartphone cover glass, automotive display glass, and camera lens cover glass.

Sapphire glass applications, including smartphone sapphire covers, camera sapphire lenses, and sapphire light strips (for LED lighting).

Other optical glass types, such as filters and mirrors.

Common glass materials, including borosilicate glass, quartz glass, white glass, automotive mirrors, and bathroom glass.

| Application Industry | Types of Glass Used |

| Glass Processing Industry | Optic/UTG/Willow/Brittle Biomedical glass |

| Real Estate Industry | Architectural decoration, Bathroom glass |

| Automobile Industry | Car glass/Instrumentation panel glass |

| Communication Media Industry | Mobile/Watch sapphire cover, Camera/CCTV Lens glass |

| Home Appliance Industry | Home appliance glass panel, Lighting glass |

| New Energy Industry | Photovoltaic glass |

| Glass Type | Description |

| Ultra Clear Class | Refers to a category of glass with exceptional clarity. |

| Plain White Glass | A type of glass that is uniformly white and often used for various applications. |

| High Borosilicate Glass | A type of glass known for its high boron content, which provides greater resistance to thermal stress. |

| Quartz Glass | A high purity glass that is low in impurities and has unique properties such as a high melting point and resistance to chemicals. |

| Phone Glass Cover | The protective glass used as a cover for smartphone screens. |

| Car Glass | Glass used in automotive applications, such as windshields or windows. |

| Camera Glass Cover | The protective glass cover for camera lenses or display screens. |

| LCD Screen | The liquid crystal display screen used in a variety of electronic devices. |

| K9 Glass | A type of optical glass often used in the manufacturing of optical instruments. |

Key Features

High-power red laser source: Equipped with high-performance components including seed sources from leading international brands, ensuring stable and reliable operation.

Non-contact drilling: Specially designed glass drilling head with all lenses imported from the USA; delivers fine laser spots and long focal depth.

Precision motion system: X/Y axes adopt linear motors, German digital gratings, Taiwan ball screws and guide rails, and Israeli drivers — capable of 24/7 stable operation without failure.

Accurate positioning: Integrated CCD alignment system with telecentric lens for precise target recognition

Core Advantages

The PRECISE CNC glass laser drilling machine features a self-developed control system, high-end customized laser source, and dual-driven linear motors, ensuring exceptional precision. Compared to traditional CNC or waterjet processing, it offers irreplaceable advantages.

Laser drilling is a non-contact process that is easy to operate, fully automatic, consumable-free, pollution-free, low in energy consumption, and highly efficient. In contrast, traditional CNC drilling suffers from environmental pollution, high tool wear, severe edge chipping, high scrap rates, and low efficiency.

PRECISE CNC's laser drilling machine completely overcomes these shortcomings, significantly reducing manufacturing costs and increasing product profitability for processing manufacturers.

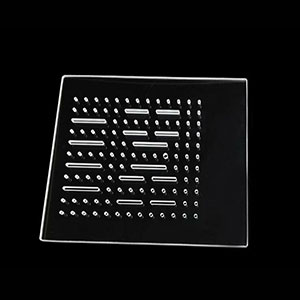

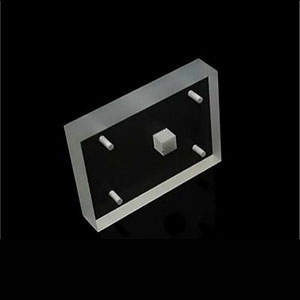

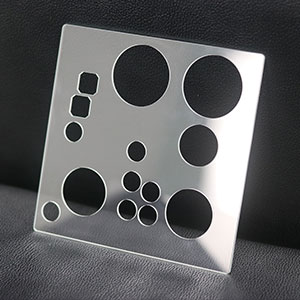

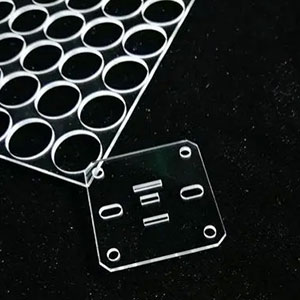

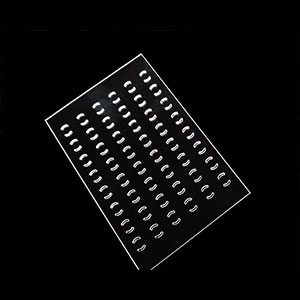

Glass Laser Drilling Machine Samples

Glass Laser Drilling Machine Applications

Glass Laser Drilling Machine Testimonials

Glass Laser Drilling Machine FAQs

A: Our laser drilling machine is suitable sapphire glass, borosilicate glass, optical glass, and ultra-thin glass used in electronics, automotive, and medical industries.