Product Specification

| Model No. | PR-SC3015 PR-SC4020 PR-SC6025 |

| Laser Type | Fiber Laser |

| Laser Wave Length | 1064nm |

| Working Area | 3050*1530mm ( can be customized ) |

| Working Table | Sawteeth |

| Maximum Idle Running Speed | 120m/min |

| Maximum acceleration | 1.5G |

| Positioning Accuracy | ±0.02mm/m |

| Repeated Positioning Accuracy | ±0.01mm |

| Working Voltage | AC 380V±10% 50/60HZ |

| Decoil and Flattener speed | 8-15m/min |

| Roller quality | 13 pieces |

| Uncoiling thickness | 0.5-1.5mm SS;0.5-3.5mm Aluminum,galvanized |

| Material width | 0-1500mm |

| Material Diameter | 470-530mm/570-630mm |

| Rated Load | 8T |

| Laser Source Cooling Type | Water cooling |

| Work Environment | 0-45℃,Moisture 45-85% |

| Cutting Gas | Nitrogen gas/Oxgen gas/Air |

| System Identification File Format | DXF, DWG, PLT, ENG ,G file |

Main Configurations

| Item | Brand | Brand Location | Specification |

| Laser Source | Max/Raycus | Shenzhen/Wuhan China | 3000W (Optional powers: 1000W, 1500W, 2000W, 3000W, 4000W) |

| Laser Cutting System | Empower bus system | Shanghai, China | |

| Laser Cutting Head | Raytools | Shanghai, China | |

| Lathe Bed | Integrated welding | Jinan, China | |

| Decoiler | PRECISE CNC | Jinan, China | |

| Straightener | Leadshine | Shenzhen, China | |

| Automatic unloading system | PRECISE CNC | Jinan, China | |

| Wifi Wireless Remote Control | Cypcut | Shanghai, China | |

| Laser Cutting Technology Database | Cypcut | Shanghai, China | |

| Cutting Abnormal Alarm | YES | ||

| Laser Abnormal Alarm | YES | ||

| Auxiliary gas low pressure alarm | YES | ||

| Electrical component | Schneider | Germany | Industrial grade |

Steel Coil Metal Fiber Laser Cutting Machine Features and Advantages

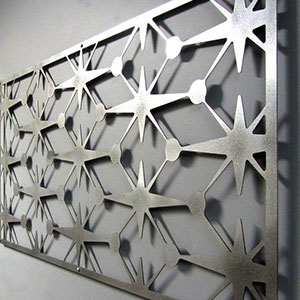

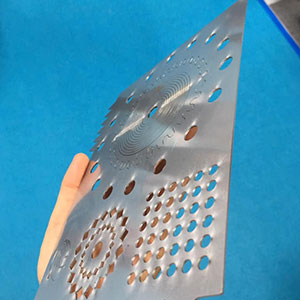

Steel Coil Metal Fiber Laser Cutting Machine Samples

Steel Coil Metal Fiber Laser Cutting Machine Samples Applications

Steel Coil Metal Fiber Laser Cutting Machine Testimonials

Steel Coil Metal Fiber Laser Cutting Machine FAQs

A: The working principle of a fiber laser cutting machine is based on the use of a high-powered laser beam to melt, burn, or vaporize the material being cut. Here’s a breakdown of the process:

1.Laser Generation: The machine generates a laser beam using a fiber optic laser source. The laser source typically uses a fiber laser (such as YAG or ytterbium-doped fiber) that is pumped with light from diodes. The laser beam is then transmitted through the fiber optic cable.

2.Beam Focusing: The laser beam is directed and focused onto the material using a set of mirrors and a focusing lens. The focused beam has very high energy density and is able to concentrate on a small spot on the material’s surface.

3.Material Interaction: When the laser beam hits the material, it rapidly heats up the surface, causing the material to melt, burn, or vaporize. The cutting area is typically assisted by auxiliary gases (like nitrogen, oxygen, or compressed air), which help blow away the molten material and improve the cut quality.

4.Cutting Process: As the laser beam moves across the material, the heat melts or vaporizes the material in the path of the beam. The cutting head is typically controlled by a CNC system, which precisely guides the laser beam to cut along the desired path.

5.Cooling: During the cutting process, the material around the laser-cut area cools and solidifies quickly, allowing for clean, precise cuts with minimal distortion.

Fiber laser cutting machines are favored for their high cutting precision, speed, and efficiency, particularly when cutting metals such as stainless steel, aluminum, and carbon steel. The fiber laser’s ability to focus energy tightly on the cutting area results in high-quality, narrow kerf widths, and minimal heat-affected zones (HAZ).