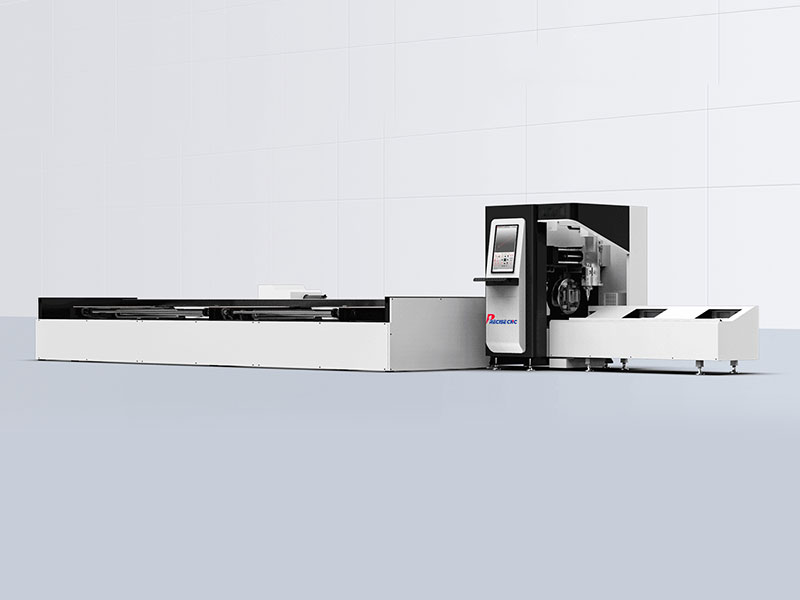

Product Name: The most economical solution for closed and small tubes cutting

Model: PR-A6012,PR-AB6012,PR-A6018

Laser Power: 0.04~0.24kw

Dimension: 420.91x101.18x74.8

Application: High Speed Laser Tube Cutting Machine Applications,Kitchenware Manufacturing,Agriculture Machinery,Furniture Manufacturing,Architecture Industry,Automotive Manufacturing,Aerospace Industry,Shipbuilding Industry,Railway Facilities,Petroleum Industry,Sports Equipment

Product Specification

| Model No. | PR-A6012 | PR-AB6012 | PR-A6018 | ||

| Pipe Diameter (in) | Φ口0.31 -4.72 | Φ口8 -4.72 | Φ口0.39 -7.09 | ||

| Cutting Tailing (in) | ≥2.56 | ||||

| Chuck Speed | 7.87 r/min | 7.87 r/min | 4.72 r/min | ||

| Cutting Length | 248.03 | ||||

| Max.Unloading Length | 236.22 | ||||

| Dimensions (in) | 420.91x101.18x74.8 | ||||

| Laser Power | 0.04~0.24kw | ||||

| Pipe types | round tubes, square tubes, rectangular tubes,elliptical tubes,etc metal closed Tubes | ||||

High Speed Laser Tube Cutting Machine Features and Advantages

Reasons to choose PRECISE CNC A-series

High Speed Laser Tube Cutting Machine Samples

High Speed Laser Tube Cutting Machine Applications

High Speed Laser Tube Cutting Machine Testimonials

High Speed Laser Tube Cutting Machine FAQs

A: The working principle of a fiber laser cutting machine is based on the use of a high-powered laser beam to melt, burn, or vaporize the material being cut. Here’s a breakdown of the process:

1.Laser Generation: The machine generates a laser beam using a fiber optic laser source. The laser source typically uses a fiber laser (such as YAG or ytterbium-doped fiber) that is pumped with light from diodes. The laser beam is then transmitted through the fiber optic cable.

2.Beam Focusing: The laser beam is directed and focused onto the material using a set of mirrors and a focusing lens. The focused beam has very high energy density and is able to concentrate on a small spot on the material’s surface.

3.Material Interaction: When the laser beam hits the material, it rapidly heats up the surface, causing the material to melt, burn, or vaporize. The cutting area is typically assisted by auxiliary gases (like nitrogen, oxygen, or compressed air), which help blow away the molten material and improve the cut quality.

4.Cutting Process: As the laser beam moves across the material, the heat melts or vaporizes the material in the path of the beam. The cutting head is typically controlled by a CNC system, which precisely guides the laser beam to cut along the desired path.

5.Cooling: During the cutting process, the material around the laser-cut area cools and solidifies quickly, allowing for clean, precise cuts with minimal distortion.

Fiber laser cutting machines are favored for their high cutting precision, speed, and efficiency, particularly when cutting metals such as stainless steel, aluminum, and carbon steel. The fiber laser’s ability to focus energy tightly on the cutting area results in high-quality, narrow kerf widths, and minimal heat-affected zones (HAZ).