Product Name: Continuous Wave Fiber Laser Cleaning Machine For Rust Cleaning

Model: PR-CLC1500/2000/3000

Laser Power: 1500W, 2000W, 3000W

Application: The continuous wave (CW) fiber laser cleaning machine is widely used for high-speed, large-area surface cleaning in industrial applications. Its stable, continuous output makes it ideal for removing rust, paint, oil, coatings, oxide layers, and welding slag on metal surfaces.

Automotive manufacturing,Architecture Industry,Aerospace Industry,Shipbuilding Industry,Railway Facilities,Petroleum Industry

It is best suited for heavy-duty, production-line cleaning tasks where speed and uniformity are critical.

General introduction

Main Feature

Machine Parameters

| Machine Name | Handheld Continuous Fiber Laser Cleaning Machine |

| Model No. | PR-CLC1500/2000/3000 |

| Laser Power | 1500W 2000W 3000W |

| Laser Wave Length | 1080nm |

| Laser Source | Raycus / Max / JPT/ IPG |

| Fiber Length | 10M |

| Cooling Mode | Water cooling |

| Application | Rust cleaning, Surface Paint Cleaning |

| Cleaning Width | 300MM |

| Whether anti-high reflection | Yes |

| leaning Materials | Metal Rust Oil Dust Coating |

| Working Voltage | AC220V / 50Hz / 60HZ AC380V 50Hz/60Hz |

| Package Size | 162*70*144cm |

| Gross Weight | 320kgs |

Optional

Packing size: Machine: 167*72*145 cm Water chiller: 82*57*109.5cm

Gross weight :398KG

Main Configurations

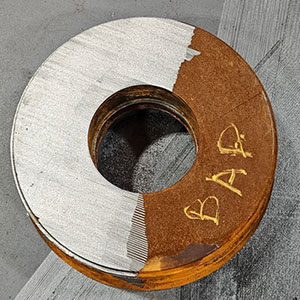

Laser Cleaning Machine Samples

Laser Cleaning Machine Applications

Laser cleaning VS Traditional Cleaning Methods

| Aspect | Laser Cleaning Method | Traditional Cleaning Method |

| Environmental impact | Eco-friendly with low waste generation and minimal emissions. | It may produce chemical waste, abrasive dust, or wastewater, which can lead to environmental pollution. |

| Efficiency and Productivity | Reduces cleaning cycle time, maximizes efficiency, drives higher productivity | Can require extensive manual work, along with the preparation and cleanup of abrasive materials or chemical agents. |

| Regulatory Compliance | Ensures industries comply with standards for cleanliness, quality assurance, and environmental regulations. | May need extra steps to meet environmental and safety standards. |

| Cost Effectiveness | Requires a higher upfront investment, but delivers long-term savings through lower consumable usage and reduced maintenance expenses. | Lower upfront cost, but may lead to recurring expenses for consumables, disposal, and maintenance. |

Laser Cleaning Machine Testimonials

Laser Cleaning Machine FAQs

A: CW stands for Continuous Wave. Unlike pulsed lasers, CW lasers emit a constant laser beam, ideal for removing paint, rust, oil, and other surface contaminants on metal or hard surfaces.