Product Name: Luggage Case Pulse Laser Cleaning Machine

Model: PR-PLC200SL,PR-PLC200ML,PR-PLC300SL,PR-PLC300ML,PR-PLC500ML

Laser Power: 200W, 300W,500W

Application: Automotive manufacturing,Architecture Industry,Aerospace Industry,Shipbuilding Industry,Railway Facilities,Petroleum Industry

General introduction

Working Principle of Pulse Laser Cleaning Machine

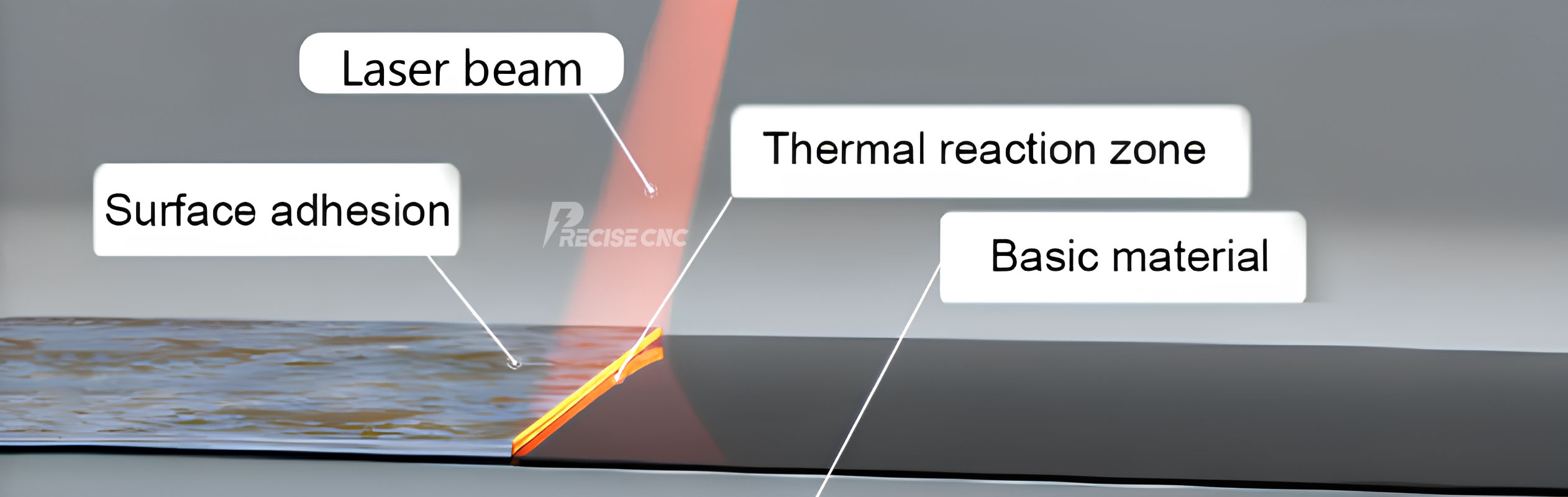

The pulse laser cleaning machine operates by emitting a high-energy laser beam in short, controlled bursts. When this laser beam is directed onto a contaminated surface, it interacts with the surface adhesion layer—such as rust, paint, oil, or oxides—without affecting the base material.

As the laser energy is absorbed by the contaminants, a thermal reaction zone is rapidly formed. This sudden rise in temperature causes the unwanted layer to either vaporize or peel off due to the difference in absorption rates and thermal expansion between the contamination and the substrate.

Because the energy is precisely controlled and the laser pulses are very short, the cleaning process does not damage the basic material, ensuring a safe, efficient, and contactless method of surface treatment. The higher the mj value, the stronger the single pulse energy and the less damage to the cleaning substrate.

Main Feature

Struggling with stubborn rust, oil, or surface residues?

Our High-Power Pulsed Laser Technology delivers intense energy bursts that break through contamination fast—no mess, no hassle.

Need precise results without damaging your materials?

Enjoy fine cleaning capabilities that allow meticulous work, even on sensitive surfaces. The non-contact, non-abrasive method ensures your base material stays intact.

Tired of slow, costly cleaning methods?

This solution offers high efficiency, dramatically reducing cleaning time and cutting operational costs. Say goodbye to chemicals and endless consumables.

Worried about training time or complex controls?

With a user-friendly interface and ergonomic design, operators can get started quickly—with minimal effort and maximum comfort.

Why It Works for You

Superior Cleaning Performance – Achieve next-level cleanliness for peak performance.

Cost-Effective – Save on consumables and reduce maintenance costs.

Eco-Friendly – No harsh chemicals. Less waste. Greener workplace.

Versatile Across Industries – Perfect for metals, composites, and more.

From manufacturing to maintenance, this laser cleaner makes your job easier, faster, and cleaner

Machine Parameters

JPT Pulse Laser source Parameters

| Characteristic\ Laser Type | YDFLP- CL2-200-1 | YDFLP- CL2-300-1 | YDFLP- CL2-200-5 | YDFLP- CL2-300-5 | YDFLP-CL2-300-10 | |||||

| M²(typical) | 1.5 | 5 | 12 | |||||||

| Delivery Cable Length | m | 5 | ||||||||

| Average Output Power | W | >200 | >300 | >200 | >300 | >300 | ||||

| Maximum Pulse Energy | mJ | 2 | 5 | 15 | ||||||

| Pulse Repetition Rate Range | kHz | 1-3000 | ||||||||

| Pulse Width | ns | 13-500 | ||||||||

| Output Power Instability | % | <5 | ||||||||

| Cooling Method | Air-cooled | |||||||||

| Power Supply Voltage (DC) | V | 48V | ||||||||

| Power Consumption | W | <700 | <1000 | <700 | <1000 | <1000 | ||||

| Power supply current requirement | A | >14.6 | >20.8 | >14.6 | >20.8 | >20.8 | ||||

| Central Wavelength | nm | 1064 | ||||||||

| Emission Bandwidth@3dB | nm | <15 | ||||||||

| Polarization | Random | |||||||||

| Anti-Reflection Protection | Yes | |||||||||

| Output Beam Diameter | mm | 6±1 | 6±1 | 7±1 | 7±1 | 7±1 | ||||

| Output Power Tuning Range | % | 0~100 | ||||||||

| Ambient Temperature Rang | ℃ | 0~40 | ||||||||

| Storage Temperature Range | ℃ | -10~60 | ||||||||

| Dimensions | mm | 340*265*100 | ||||||||

| QCS Size | 153*∅17 | |||||||||

Some laser cleaning application parameters for your reference

| Type | Product | Materials | Cleaning type | Cleaning efficiency | Cleaning result |

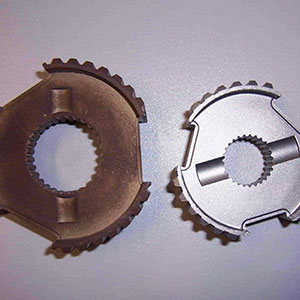

| Rust removal | 3 claw chuck | Alloy | Standard | 1700mm2/s | Can completely remove the coating,and no damage on the surface. |

| Angel steel | Q235 (Carbon steel) | 1400mm2/s | |||

| Carbon steel tube | Carbon steel | 2000mm2/s | |||

| Drive gear | 40cr (surface tempering+high efficiency) | 1400mm2/s | |||

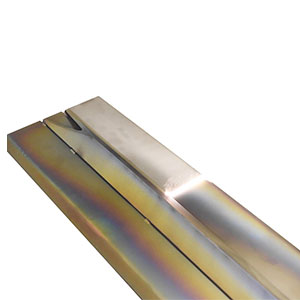

| Pre and post treatment of welded material | Water pipe joint | Alloy casting iron | 1800mm2/s | ||

| Steel water sink | SUS304 | 1700mm2/s | |||

| Paint removal | Bent metal plate | Carbon steel | 2000mm2/s | ||

| Greasy dirt treatment | Auto parts | Stainless steel(Greasy dirt on surface ) | 2000mm2/s |

Main Configurations

Laser cleaning VS Traditional Cleaning Methods

| Aspect | Laser Cleaning Method | Traditional Cleaning Method |

| Environmental impact | Eco-friendly with low waste generation and minimal emissions. | It may produce chemical waste, abrasive dust, or wastewater, which can lead to environmental pollution. |

| Efficiency and Productivity | Reduces cleaning cycle time, maximizes efficiency, drives higher productivity | Can require extensive manual work, along with the preparation and cleanup of abrasive materials or chemical agents. |

| Regulatory Compliance | Ensures industries comply with standards for cleanliness, quality assurance, and environmental regulations. | May need extra steps to meet environmental and safety standards. |

| Cost Effectiveness | Requires a higher upfront investment, but delivers long-term savings through lower consumable usage and reduced maintenance expenses. | Lower upfront cost, but may lead to recurring expenses for consumables, disposal, and maintenance. |

| LASER CLEANING★ | MECHANICAL CLEANING | ULTRASONIC CLEANING | DRY-ICE CLEANING | SANDBLASTING | CHEMICAL CLEANING | |

| Contact / No Contact | No Contact★ | Contact | Contact | No Contact★ | Contact | Contact |

| Substrate Damage | No Damage★ | With Damage | No Damage★ | No Damage★ | With Damage | With Damage |

| Precision | High★ | Low | Low | Low | Low | Low |

| Efficiency | High★ | Low | Medium | Medium | Medium | Low |

| Consumable | No★ | Grinding wheel/sandpaper | Detergent | Dry Ice | Specialized Abrasive | Chemical Detergent |

| Result | Very Good Quality★ | Medium | Good | Good | Medium | Medium |

| Eco-friendly | No Pollution★ | With Pollution | No Pollution★ | No Pollution★ | With Pollution | Heavy Pollution |

| Operation | Easy★ | Easy★ | Easy★ | Easy★ | Easy★ | Complex |

| Safety | High Safety★ | Low Safety | High Safety★ | Low Safety | Low Safety | Low Safety |

Laser Cleaning Machine Samples

Laser Cleaning Machine Applications

Laser Cleaning Machine Testimonials

Laser Cleaning Machine FAQs

A: A pulse laser cleaning machine uses high-energy pulsed laser beams to remove contaminants like rust, paint, oil, and oxides from various surfaces. It works through rapid heating and vaporization, without damaging the base material.