Product Name: Glass Laser Cutting Machine

Model: PR-PIC40/50/60/70/80/90

Laser Power: Infrared picosecond laser 40w-90w CO2 RF laser 100w-350w

Application: Consumer Electronics,.Home Appliance Glass,Architectural Decorative Glass,Automotive Glass,Optical & Solar Glass

Inquire

General introduction

A picosecond laser cutting machine is a high-performance, high-efficiency, high-quality laser cutting machine, mainly cutting glass materials, such as blue glass, white glass, ultra-clear glass, etc. With the development of various industries, there are more and more glass applications.

A picosecond laser glass-cutting machine is a high-efficiency, automatic glass-cutting machine, that uses a picosecond laser source and RF CO2 laser source to cooperate with glass-cutting technology.

The glass-cutting industry is widely used, for example, glasses manufacturers, lens manufacturing, camera industry, optical lens production, medical industry, lens production in atomized instruments, smart wearable watch industry, watch glass dial production, automotive industry, automotive rearview mirror glass cutting, cosmetic industry, cosmetic lens cutting.

| Model No. | PR-PIC40/50/60/70/80/90 |

| Laser type | Infrared picosecond laser (40/50/60/70/80/90w) for cutting and CO2RF laser (100/120/150/350w) for splitting |

| Laser power | Infrared picosecond laser 40w-90w CO2 RF laser 100w-350w |

| Wave length | Infrared picosecond laser 1064nm CO2 RF laser 10.6µm |

| Pulse Frequency | 1Hz - 1000kHz |

| Pulse width | <10ps |

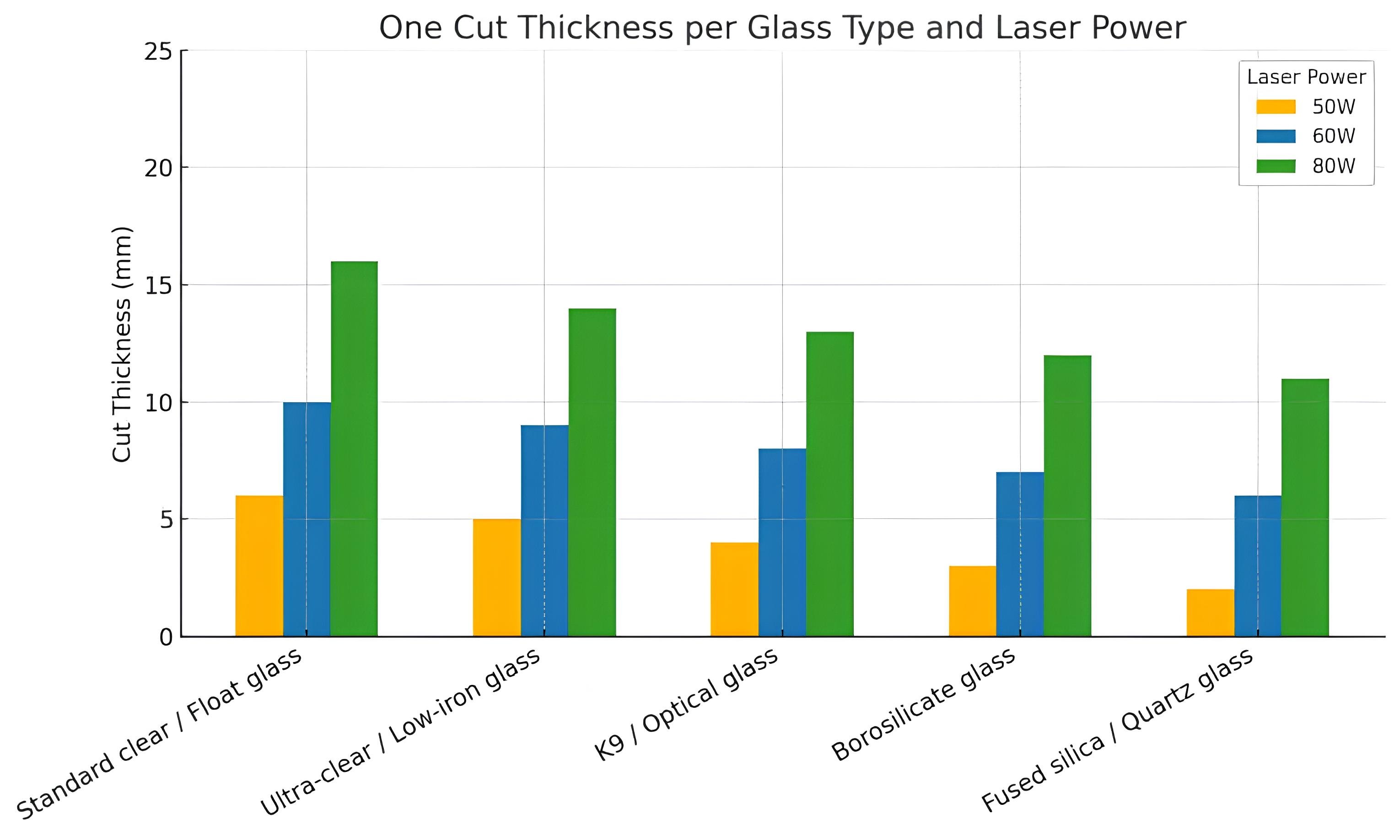

| Cutting thickness | 0.1-25mm around |

| Cooling mode | Water cooling |

| Brand name | PRECISE CNC |

| Laser cutting head | Bessel |

| Acceleration | 1G |

| Linear Speed | Up to 1000mm/s |

| Minimum Cutting Burr | ≤5μm |

| Processing speed | 0-500mm/s |

| Platform repeated positioning accuracy | ± 2μm |

| Platform dynamic positioning accuracy | ± 5μm |

| Cutting accuracy | ±0.01mm |

| Camera positioning accuracy | ± 0.01mm |

| Applicable materials | Ultra-white glass, ordinary white glass, Borosilicate glass, Optical glass, Quartz glass,lstained glass, laminated and coated glass, sapphire glass, mobile phone panel, camera glass cover,k9 glass, LCD screen, etc. |

| Power Requirement | 380V 3PH 50/60HZ |

| Machine weight | About 3500kgs |

Glass Laser Cutting Machine main configurations

Glass Laser Cutting Machine Video

Main Advantages Features

Incorporating multiple functions into one to creates more value for customers.

Advanced Design and Construction

Features a fully enclosed, integrated structure with a modern and streamlined appearance.

Built on a marble or granite base, incorporating a gantry and column architecture to ensure structural stability.

Ergonomic and User-Friendly Interface

Equipped with a human-centric workstation layout designed to enhance operator comfort and usability.

Incorporates a user-friendly human-machine interface for efficient operation.

Precision and Cutting Technology

Utilizes a side-axis CCD camera-assisted positioning system to ensure high accuracy in workpiece alignment.

Integrated linear motor system supports high-speed cutting, significantly increasing processing efficiency.

Laser Head and Processing Capabilities

Features a customized laser cutting head with a positive pressure sealing device to protect internal components from environmental exposure and extend service life.

Environment friendly

Supports fully enclosed operation with optional dedicated dust extraction systems to maintain a clean working environment.

No pollution, no wastewater and no powder.

| Category | Picosecond Laser Cutting Machine | Water Jet Cutting Machine |

| Cutting Mechanism | Utilizes ultrashort pulse laser (cold light ablation) to evaporate glass at the microscopic level | Uses high-pressure water mixed with abrasives to cut glass via mechanical erosion |

| Precision | Extremely high, reaching micron-level accuracy; ideal for fine structures | Medium to high precision, but less refined than laser cutting |

| Heat-Affected Zone (HAZ) | Extremely low; cold processing avoids thermal damage | No thermal effect; purely mechanical cutting |

| Edge Quality | Smooth, burr-free, and crack-free edges; no post-processing required | Rough edges with possible chipping; often requires polishing |

| Cutting Thickness Range | Typically suitable for thin to medium glass (0.1–5 mm) | Capable of cutting thicker glass (up to 200 mm), but with lower precision |

| Processing Speed | Fast for thin glass; up to 100–500 mm/s | Slower, especially with thicker materials requiring multiple passes |

| Material Loss | Minimal, no tool wear, high efficiency | Significant loss due to abrasive use |

| Environmental Impact | Clean process, no hazardous waste generated | Generates abrasive-containing sludge, requiring environmental treatment |

| Cost Efficiency | Higher initial investment, but low operational costs | Lower initial cost, but higher long-term consumable and treatment expenses |

| Automation & Integration | Easy to integrate with CNC or robotic systems | More complex to automate, requiring more intricate coordination |

| Application Industry | Types of Glass Used |

| Glass Processing Industry | Optic/UTG/Willow/Brittle Biomedical glass |

| Real Estate Industry | Architectural decoration, Bathroom glass |

| Automobile Industry | Car glass/Instrumentation panel glass |

| Communication Media Industry | Mobile/Watch sapphire cover, Camera/CCTV Lens glass |

| Home Appliance Industry | Home appliance glass panel, Lighting glass |

| New Energy Industry | Photovoltaic glass |

| Glass Type | Description |

| Ultra Clear Class | Refers to a category of glass with exceptional clarity. |

| Plain White Glass | A type of glass that is uniformly white and often used for various applications. |

| High Borosilicate Glass | A type of glass known for its high boron content, which provides greater resistance to thermal stress. |

| Quartz Glass | A high purity glass that is low in impurities and has unique properties such as a high melting point and resistance to chemicals. |

| Phone Glass Cover | The protective glass used as a cover for smartphone screens. |

| Car Glass | Glass used in automotive applications, such as windshields or windows. |

| Camera Glass Cover | The protective glass cover for camera lenses or display screens. |

| LCD Screen | The liquid crystal display screen used in a variety of electronic devices. |

| K9 Glass | A type of optical glass often used in the manufacturing of optical instruments. |

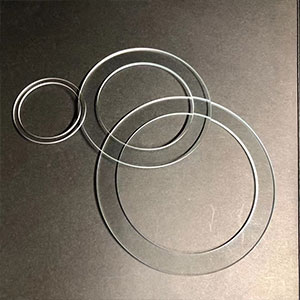

| Filter Cutting | The process of cutting glass or other materials to create filters for various applications. |

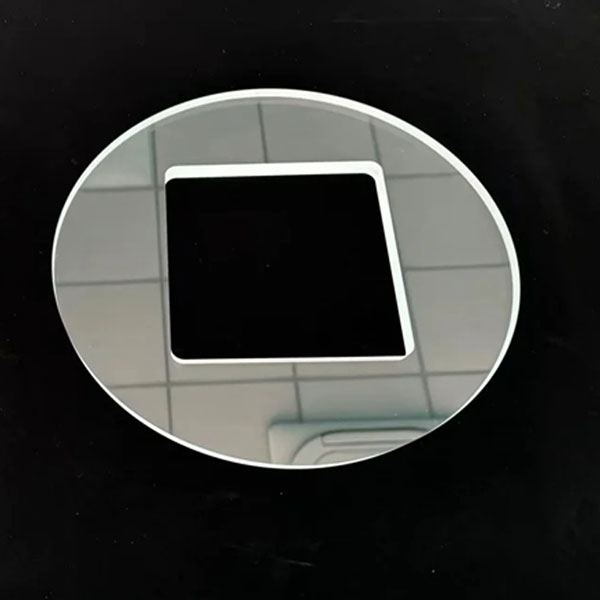

| Mirror Cutting | The process of cutting glass to produce mirror surfaces for decorative or functional use. |

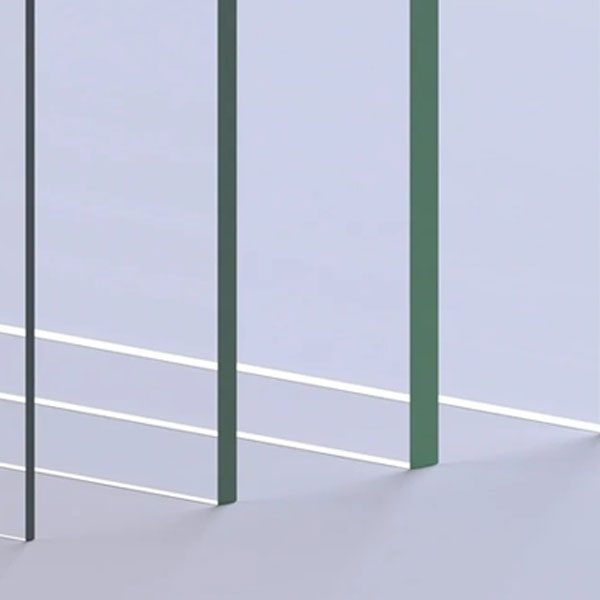

Glass Laser Cutting Machine Samples

Glass Laser Cutting Machine Applications

Glass Laser Cutting Machine Testimonials

Glass Laser Cutting Machine FAQs

Our laser systems can cut various glass types including:

Soda-lime glass (i.e. Sodium-calcium glass): both ultra-white glass and ordinary white glass belong to sodium-calcium glass

Borosilicate glass

Ultra-thin glass (e.g., Gorilla Glass)

Optical glass

Quartz glass

Sapphire glass

Stained glass

Laminated and coated glass