If you work in metal fabrication—whether you’re building automotive parts, construction scaffolding, or even metal furniture—you know one thing: tubular materials are tricky to cut well. You need precision, speed, and clean edges, but traditional tools like saws or plasma cutters often fall short. That’s where tube laser cutting machines come in. They’ve totally changed how we process pipes, tubes, and profiles—but if you’re new to them, you probably have questions: What exactly is this machine? Why do prices vary so much? And why should you buy direct from a factory instead of a middleman?

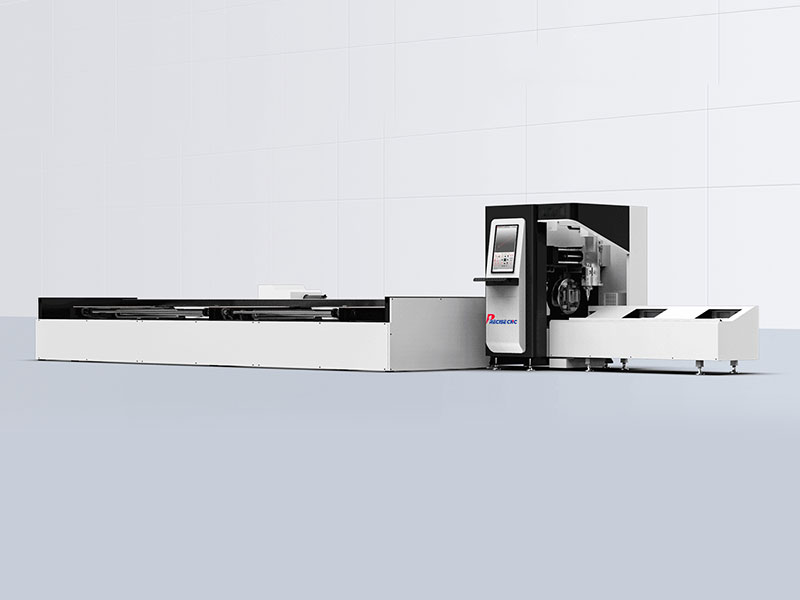

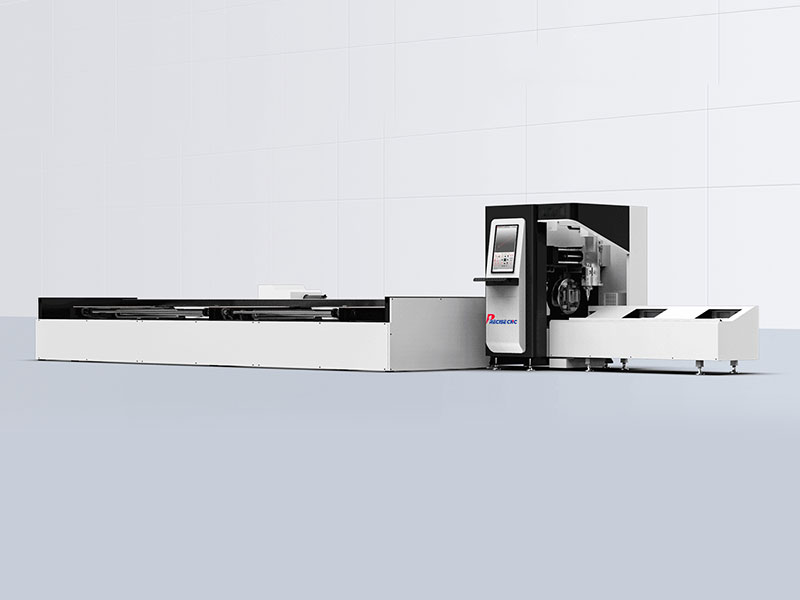

As someone who’s been in the CNC laser game for over a decade (we’re Jinan Precise CNC, a leading Chinese manufacturer), let’s break this down in plain terms—no jargon, just what you need to know.

First: What Is a Tube Laser Cutting Machine?

Put simply, it’s a specialized tool that uses laser technology to cut, drill, or add bevels to metal tubes and profiles—cleanly, precisely, and way faster than old-school methods.

Here’s the difference from, say, a saw: Instead of physically grinding through metal (which leaves burrs, wastes material, and limits complexity), a tube laser uses a super-focused laser beam to melt or vaporize the metal. The result? Edges that don’t need sanding, intricate cuts (even on round, square, or oval tubes), and almost no scrap. It’s a game-changer for anyone working with tubular metal.

How Does It Actually Work?

You don’t need to be an engineer to get the gist—here’s the basics:

The Laser Source: Most metal tube lasers use fiber lasers (they’re tough, fast, and perfect for metals like steel or aluminum).

The Chuck System: A rotary chuck holds the tube steady and spins it as needed—so the laser can cut all around the tube, not just one side.

CNC Controls: It’s all automated. You program the design (think: holes, notches, custom shapes), and the machine moves the tube (or the laser) along multiple axes to hit every spot perfectly.

No more manual measuring, no more uneven cuts—just consistent, fast work.

Where Do People Actually Use These Machines?

If there’s metal tubing involved, chances are a tube laser is behind it. Here are the big industries we see:

Automotive: Exhaust pipes, roll cages, chassis parts—all need precise cuts to fit together.

Construction: Scaffolding, handrails, structural supports—durability starts with clean cuts.

Furniture: Metal chair frames, table bases, shelving—intricate designs that saws can’t touch.

Aerospace: Lightweight tubing for planes/rockets—zero room for error here.

HVAC: Custom ducting, flanges, fittings—needs to be airtight, which means perfect cuts.

Why Do Tube Laser Prices Swing So Much?

We don’t quote exact prices here (every business has different needs!), but these are the 5 big factors that make a machine cost $10k vs. $100k:

1. Laser Power (Bigger = More $, But More Capable)

Fiber lasers range from 500W to 6kW+. A 500W machine works for thin tubes (think: 5mm steel), but if you’re cutting 20mm+ thick walls? You’ll need 6kW—and that means a more powerful laser source, plus a better cooling system (to keep it from overheating). More power = faster cuts and thicker materials, but also a higher price tag.

2. What Size/Type of Tubes Can It Handle?

Diameter: A machine that cuts 50mm pipes is way different from one that handles 200mm+ large tubes (bigger chucks, stronger frames = more cost).

Wall Thickness: Thicker metal needs more laser power (see above) and specialized cutting heads—both add up.

Profile Type: Round/square tubes are standard, but if you need to cut H-beams or custom shapes? The machine needs advanced chucking and axis systems, which bump up the price.

3. Automation (Saves Time, Costs More Upfront)

Manual loading/unloading is cheap, but it’s slow—especially for mass production. Here’s where automation matters:

Dual Chucks: Our Two-Chuck Side-Hanging model, for example, lets you load a new tube while the machine cuts the old one—no downtime. Game-changer for busy shops.

Robotic Loading: Some machines have robots that feed tubes automatically—great for 24/7 operation, but adds to the cost.

Software: Fancy software that does 3D nesting (fitting more cuts on one tube to reduce waste) or real-time monitoring? It’s super useful, but requires better CNC controls.

4. Precision & Speed

If you’re making aerospace parts, you need ±0.01mm accuracy—that means premium components (like high-end linear guides or servomotors). Similarly, a machine that cuts at 1000mm/s is faster than one at 500mm/s, but it needs a more powerful motor system. More precision/speed = higher cost.

5. Build Quality (Durability Costs Money)

A lightweight machine might be cheap, but it’ll shake during heavy use (ruining cuts) and break down faster. Industrial-grade machines use marble or granite bases (for stability) and tough parts (like German linear guides)—they last 10+ years, but they cost more upfront.

Why Buy Factory-Direct? (Spoiler: It’s Not Just About Price)

We’re a factory in Jinan, China (20,000㎡ facility, ISO 9001 certified), so we know the benefits of cutting out middlemen. Here’s what you actually get when you buy direct from us:

1. No More Markups

Distributors and retailers add 20-50% to the price just to make a profit. When you buy from us, you’re paying for the machine—not someone else’s commission. Transparent pricing, no hidden fees.

2. We’ll Customize It for Your Work

Need a machine that cuts 150mm stainless steel tubes? Or a custom workbench for your shop space? We don’t sell “one-size-fits-all”—we tweak chuck sizes, software, even the frame to match your needs. And since it’s factory-direct, customization doesn’t cost an arm and a leg.

3. We Build the Tech Ourselves (Less Headache Later)

Our R&D team designs our own laser heads and dual-chuck systems—we don’t rely on third-party parts. That means:

4. Global Quality at Chinese Prices

We export to 100+ countries, so every machine meets CE/RoHS standards. And because we make thousands of machines a year, we buy components in bulk—savings we pass to you. You get a machine that’s as good as European brands, but at a fraction of the cost.

5. After-Sales Support That Actually Helps

Ever bought a machine and then waited weeks for tech support? Not with us. We offer 24/7 help (phone, video call), free online training, and spare parts stocked in major markets (so you don’t wait for parts to ship from China). We’re in this for the long haul—your success is our success.

What Makes Our (Jinan Precise CNC) Machines Stand Out?

Beyond the factory perks, our tube lasers are built for real shops:

Versatility: Cut round, square, oval, or custom profiles—no need to buy a new machine for each shape.

Efficiency: Our High Efficient model cuts waste by 15% (less scrap = more money saved) and speeds up production by 30% vs. old methods.

Precision: ±0.03mm accuracy—good enough for aerospace, but practical for any shop.

Durability: Marble workbenches and linear motors keep it stable, even if you run it 8 hours a day.

Final Thought: It’s an Investment, Not Just a Purchase

A tube laser cutting machine isn’t cheap—but it’s not just a tool. It’s how you cut down on waste, speed up production, and take on more complex jobs (the ones your competitors can’t handle). And when you buy factory-direct from us, you’re getting the best balance of quality, customization, and value.

If you’re ready to stop struggling with old cutting tools and step up your tube fabrication game—let’s talk. Tell us what tubes you cut, how much you produce, and what you need—and we’ll recommend a machine that fits.

Jinan Precise CNC – Your Go-To for Laser Precision Since 2010.

Need to chat? Reach out to our team here (insert contact link) – we’re happy to answer your questions, share specs, or even send a demo video.