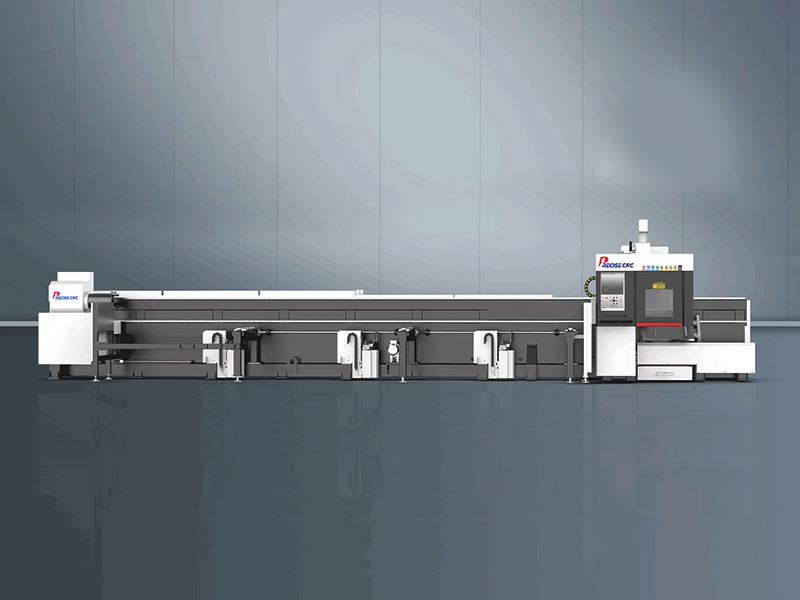

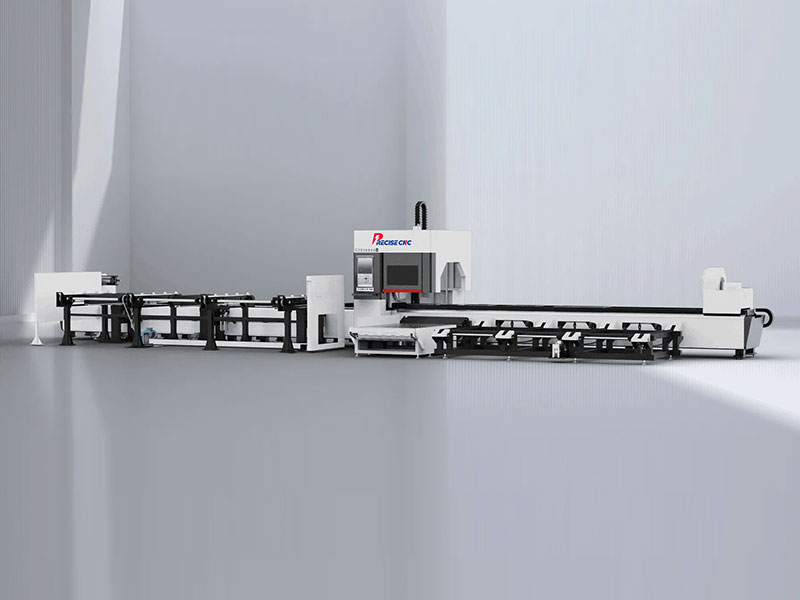

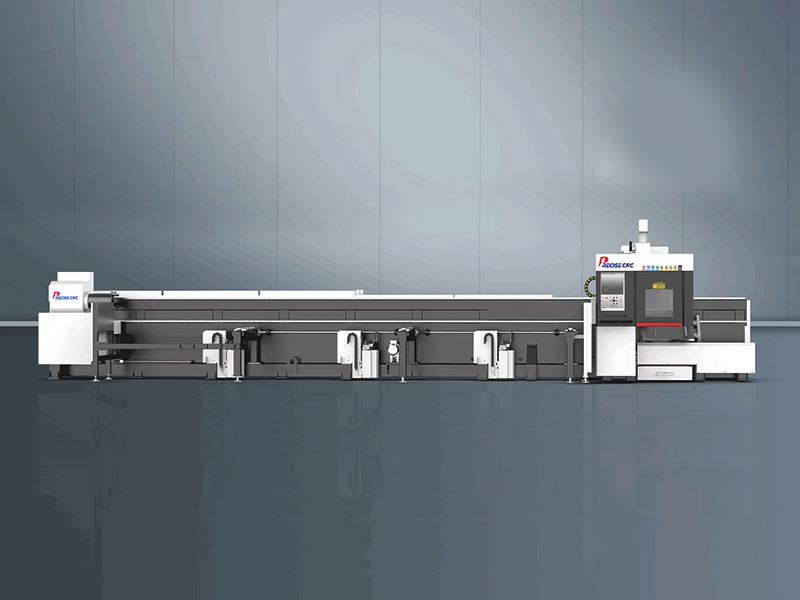

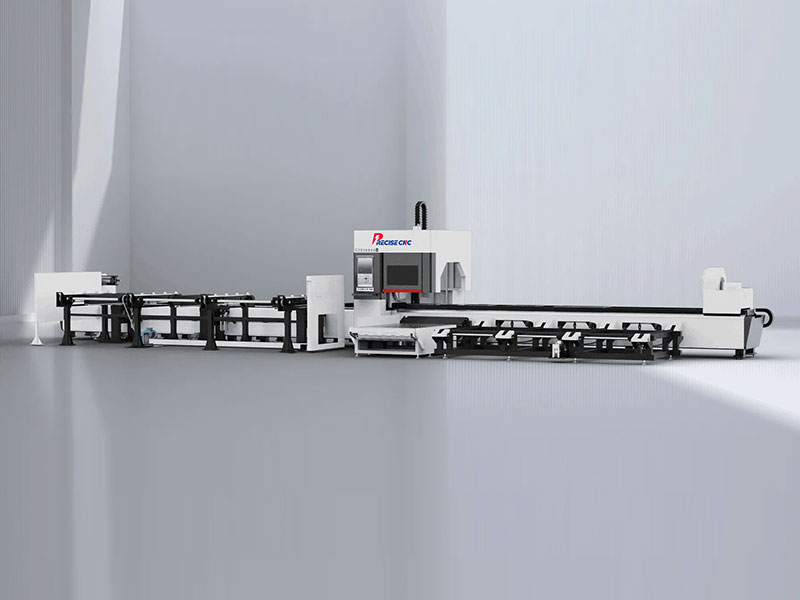

In the fast-paced world of modern manufacturing, tube laser cutting machines—especially those integrated with automatic loading & unloading systems—have emerged as game-changers. Their ability to deliver high-precision cuts, reduce manual labor, and boost production efficiency makes them essential across diverse industries. This blog not only explores key tube laser cutting machine applications but also breaks down the factors influencing their pricing. Additionally, we’ll highlight why Jinan Precise CNC Equipment Co.,Ltd, as a direct factory, offers unbeatable value for your investment.

1. Key Tube Laser Cutting Machine Applications Across Industries

The versatility of CNC laser tube cutters with automatic loading & unloading systems allows them to serve a wide range of sectors, addressing unique production needs with precision and speed.

Automotive Industry

In automotive manufacturing, our tube laser cutting machines play a pivotal role in processing metal tubes for critical components like automotive frames, exhaust systems, and suspension parts. The automatic loading & unloading system eliminates time-consuming manual material handling, enabling continuous production. Moreover, the high cutting precision (with tolerance as low as ±0.1mm) ensures tubes fit seamlessly into car chassis structures, enhancing vehicle safety, stability, and overall performance.

Aerospace Industry

The aerospace sector demands extreme precision and reliability—standards our tube laser cutters meet effortlessly. These machines cut complex-shaped metal tubes for engine components, fuel pipelines, and aircraft structural frameworks. The automatic system ensures consistent processing of high-grade aerospace metals, while the machine’s precision aligns with the industry’s strict lightweight design requirements, critical for reducing aircraft weight and improving fuel efficiency.

Furniture Manufacturing

For metal-framed furniture production, small-sized tube laser cutting machines (equipped with automatic loading & unloading) are ideal for cutting tubes into custom lengths and shapes. This flexibility enables the creation of stylish, modern furniture—such as minimalist chairs, tables, and shelves—with smooth edges and accurate dimensions. The automatic system also speeds up batch production, helping furniture manufacturers meet market demand quickly.

Medical Equipment Manufacturing

Precision is non-negotiable in medical device production, and our tube laser cutters deliver exactly that. They cut metal tubes for surgical instruments, hospital beds, and rehabilitation equipment. The high-precision cuts ensure the safety and functionality of these medical products, while the automatic loading & unloading system minimizes contamination risks by reducing human contact with materials—critical for medical industry compliance.

Electronics Industry

As electronic products trend toward miniaturization, our tube laser cutting machines provide precise solutions for manufacturing metal tube enclosures and internal support structures for devices. The automatic system handles small-diameter tubes efficiently, and the machine’s accuracy meets the industry’s high-performance requirements, ensuring electronic components fit perfectly and operate reliably.

2. Factors Affecting the Price of Tube Laser Cutting Machines

While tube laser cutters offer significant value, their pricing varies based on several key factors. Understanding these helps buyers make informed decisions:

Machine Configuration

The core components of a tube laser cutter directly impact its cost:

Laser Power: Higher power (e.g., 3000W vs. 1500W) enables cutting thicker or harder metals but increases the machine’s price.

Automatic Loading & Unloading System: Advanced systems with features like intelligent material sorting or continuous feeding cost more than basic manual or semi-automatic models, but they deliver long-term efficiency gains.

Control System: High-end CNC control systems (with user-friendly interfaces and advanced cutting software) enhance precision but add to the cost.

After-Sales Support

Comprehensive after-sales services—including on-site installation, technical training, spare parts supply, and maintenance support—contribute to the machine’s price. Reliable support minimizes downtime, making it a worthwhile investment for long-term production.

Customization Needs

Industries with unique requirements (e.g., specialized tube sizes, complex cutting patterns, or integration with existing production lines) may need customized solutions. Customizations like adapted loading mechanisms or software upgrades adjust the price to match specific production needs.

3. Our Factory’s Price Advantages: Jinan Precise CNC Equipment Co.,Ltd

As a direct manufacturer (learn more about our company here: https://www.precisecnctec.com/aboutus.html), Jinan Precise CNC eliminates the middleman markup, offering competitive prices without compromising on quality. Here’s why our pricing stands out:

No Middleman, Direct Pricing

We sell directly to customers, cutting out distributors or resellers. This means you pay for the machine itself—not extra layers of markup—resulting in significant cost savings.

In-House R&D & Production

Our professional R&D team and in-house production facilities (from component sourcing to final assembly) give us full control over costs. We avoid the high fees associated with outsourcing key processes, passing these savings to you.

Economies of Scale

With years of experience in manufacturing CNC laser equipment, we have built large-scale production capabilities. This leverages economies of scale, reducing unit costs and allowing us to offer fair, transparent pricing.

Transparent Quotations

We provide customized quotations based on your specific needs (e.g., laser power, automatic system features). There are no hidden fees—you only pay for what you need, ensuring you get the best value for your budget.

4. Why Choose Jinan Precise CNC’s Tube Laser Cutting Machines?

Beyond competitive pricing, our tube laser cutters offer unmatched advantages for your production:

Superior Precision & Efficiency: Equipped with advanced CNC technology and automatic loading & unloading, our machines deliver consistent, high-precision cuts and continuous production—ideal for high-volume orders.

Durability: We use premium components (e.g., high-quality laser sources, stable mechanical structures) to ensure long service life, reducing maintenance costs and maximizing your ROI.

Customized Solutions: Whether you need a machine for aerospace-grade cutting or furniture production, our team tailors solutions to your exact requirements.

Reliable After-Sales Service: Our professional team provides timely support—from installation to troubleshooting. We ensure your machine operates smoothly, minimizing downtime.

Get in Touch for Your Custom Solution

To explore our tube laser cutting machines and find the right fit for your industry, visit our product page: https://www.precisecnctec.com/Tube-Metal-Laser-Cutting-Machine-pl49267397.html. For inquiries or to request a customized quotation, contact us here: https://www.precisecnctec.com/contactus.html. Our team is ready to help you optimize your production with high-quality, cost-effective solutions.