In the landscape of modern manufacturing, metal laser cutting machine sale has emerged as a cornerstone of precision engineering, enabling industries to achieve unparalleled accuracy, speed, and versatility. From automotive parts to aerospace components, and from 3C electronics to new energy equipment, metal laser cutting machines have redefined production standards. This guide explores the critical aspects of metal laser cutting machine sales, including types, features, applications, and key considerations—ultimately highlighting why Jinan Precise CNC Equipment Co., Ltd. stands as a global leader in this field.

Understanding Metal Laser Cutting Machines: Types and Technologies

The metal laser cutting machine sale market offers diverse solutions tailored to specific industrial needs. The most prominent technologies include:

Fiber Laser Cutting Machines

Fiber lasers are the gold standard for metal cutting, leveraging high-power laser beams generated through optical fibers. They deliver exceptional precision (±0.001 inches tolerance) and efficiency, making them ideal for processing metals like stainless steel, aluminum, brass, and titanium. Their ability to handle thick materials (up to several centimeters) and achieve cutting speeds of 118–236 inches per minute (IPM) positions them as the top choice for large-scale manufacturing.

CO2 Laser Cutting Machines

While CO2 lasers excel in non-metal materials (wood, acrylic, fabrics), they also play a role in thin metal cutting. However, their lower power density (typically 40–100 watts for entry-level models) limits them to thinner gauges compared to fiber lasers.

Nd:YAG Laser Cutting Machines

Nd:YAG lasers offer versatility, cutting both metals and non-metals, but their higher maintenance costs and lower efficiency make them less common than fiber lasers in modern industrial settings.

Key Features Driving Metal Laser Cutting Machine Sale

Today’s metal laser cutting machine sale options are defined by advanced features that enhance productivity and precision:

1. Programmable Precision and Automation

Industrial-grade machines integrate CNC (Computer Numerical Control) systems, enabling automated cutting paths and real-time adjustments. This reduces manual intervention, minimizes errors, and ensures consistency across high-volume production runs. For example, Precise CNC’s fiber laser cutters come equipped with intuitive software that supports CAD file imports, allowing seamless design-to-production workflows.

2. Material Versatility and Thickness Capacity

Fiber laser cutting machines dominate metal processing due to their ability to handle diverse materials:

Stainless steel: Up to 20mm thickness with high-power models (6kW+).

Aluminum: Efficiently cuts 10–15mm sheets, ideal for lightweight automotive parts.

Brass and copper: Achieves clean edges with minimal heat-affected zones (HAZ).

3. Safety and Environmental Compliance

Modern machines include enclosed cutting areas, smoke extraction systems, and emergency stop protocols to protect operators. Assist gases like nitrogen or oxygen are used to prevent oxidation and improve edge quality—critical for industries like medical device manufacturing where precision is non-negotiable.

Applications: Where Metal Laser Cutting Machines Excel

The versatility of metal laser cutting machine sale solutions drives their adoption across industries:

Automotive: Cutting complex chassis components, engine parts, and decorative trims with micron-level precision.

Aerospace: Processing lightweight aluminum alloys and titanium for aircraft frames and engine components.

3C Electronics: Creating intricate parts for smartphones, laptops, and wearables, where miniaturization and accuracy are paramount.

New Energy: Fabricating battery casings, solar panel frames, and wind turbine components with high structural integrity.

How to Choose the Right Metal Laser Cutting Machine: Key Considerations

When navigating metal laser cutting machine sale options, prioritize these factors to align with your operational needs:

1. Laser Type and Power

Fiber lasers are mandatory for metal cutting; opt for 1kW+ power for industrial use (e.g., 3kW for 12mm stainless steel, 6kW for 20mm+ thickness).

CO2 lasers are suitable only for thin metals (<3mm) and non-metals, making them cost-effective for mixed-material workshops.

2. Working Area (Bed Size)

Small-scale operations (e.g., custom fabrication) may suffice with 12"x24" beds.

Large manufacturers require industrial-grade beds (e.g., 5'x10' or larger) to accommodate full-size metal sheets, reducing material waste and handling time.

3. Precision and Speed

Precision: Fiber lasers offer ±0.001 inches tolerance, critical for aerospace and medical parts.

Speed: High-power fiber lasers (6kW) can cut 1mm stainless steel at 236 IPM, ensuring rapid throughput for mass production.

4. After-Sales Support and Brand Reputation

Choose manufacturers with a proven track record of reliability. For instance, Precise CNC provides 24/7 online technical support, annual free factory training, and priority order scheduling—ensuring minimal downtime and long-term operational efficiency.

Why Choose Precise CNC for Your Metal Laser Cutting Machine Sale?

Jinan Precise CNC Equipment Co., Ltd., a leading provider in metal laser cutting machine sale, stands out through its unwavering commitment to quality, innovation, and global service:

1. Comprehensive Product Portfolio

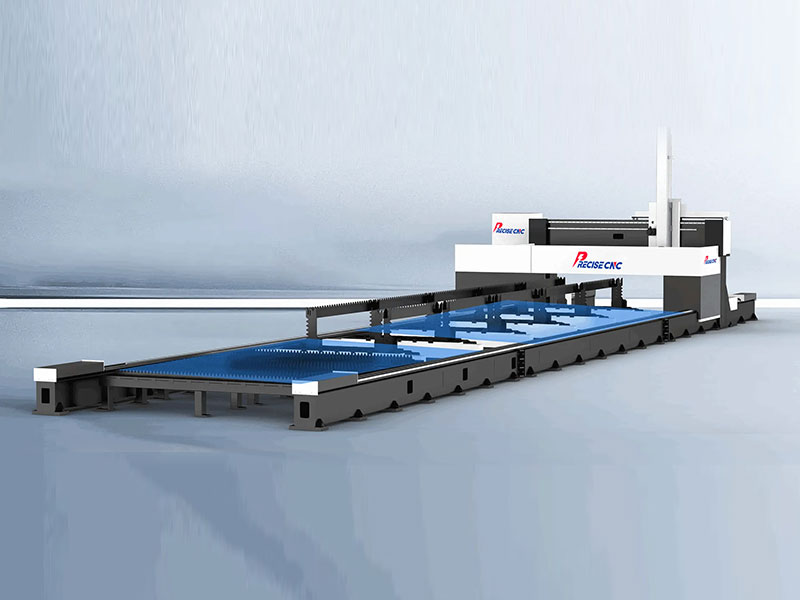

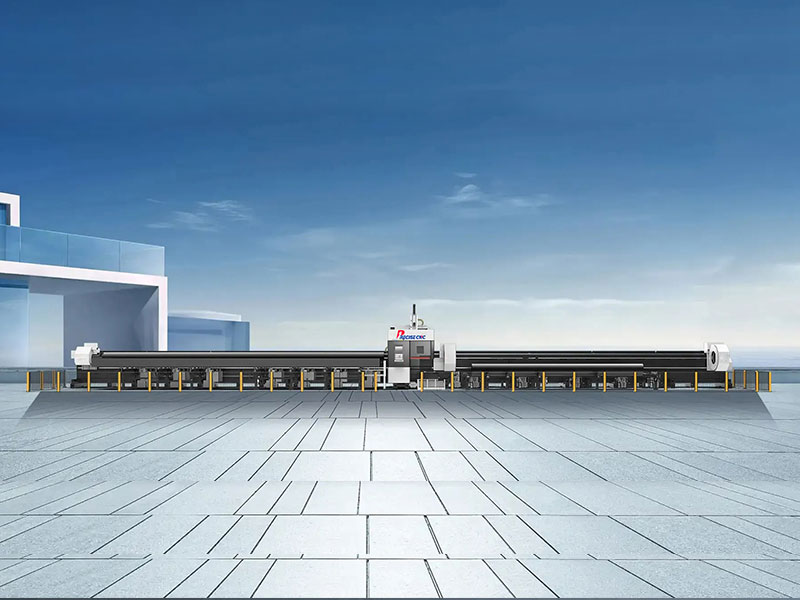

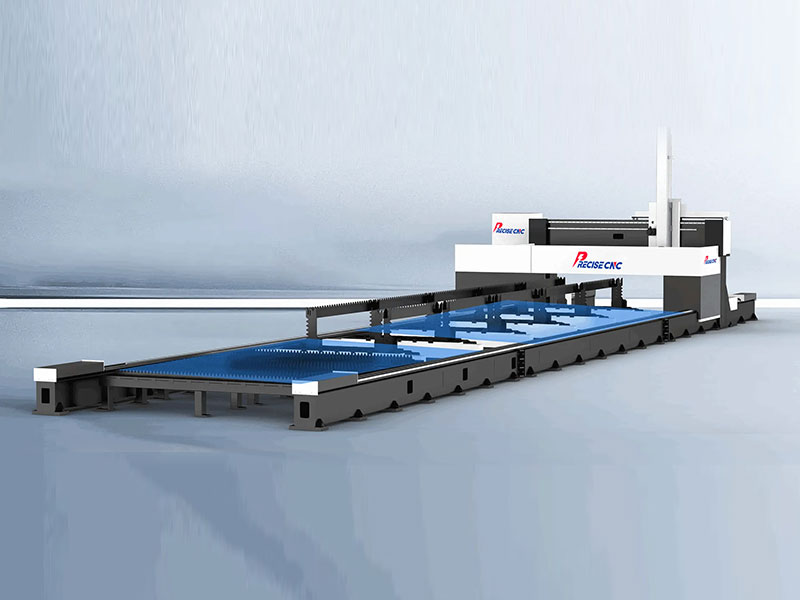

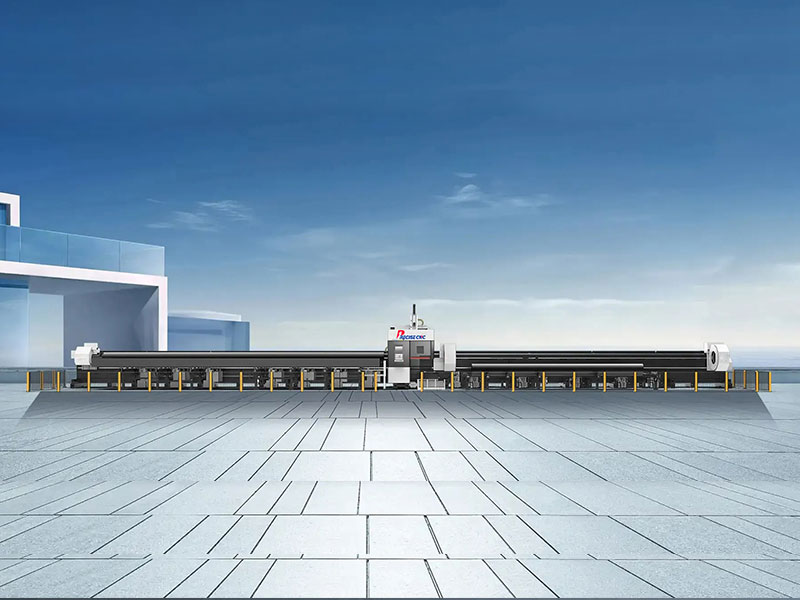

Our lineup includes sheet metal laser cutters, tube laser cutting machines, and sheet-tube combined systems, catering to diverse industrial needs. Whether you require high-power fiber lasers for thick metals or specialized glass laser cutters, we offer tailored solutions.

2. Global Reach and Quality Assurance

With a 20,000㎡ manufacturing facility and exports to 100+ countries, our machines undergo rigorous testing (ISO 9001 certified) to ensure durability and performance. Each unit is calibrated for precision before shipment, minimizing on-site setup time.

3. Industry-Specific Expertise

We specialize in serving automotive, 3C electronics, photovoltaic, medical, and new energy sectors, with R&D teams continuously innovating to meet evolving material and design challenges.

4. Unmatched Customer Support

From free annual factory training to priority order processing, our service ecosystem ensures you maximize ROI. Contact us via WhatsApp (+86-15339960292) or email (manager@precisecnctec.com) for personalized consultations.

For more details on our metal laser cutting machine sale offerings, visit our product page or contact us to speak with a technical expert. Invest in precision—choose Precise CNC for your next laser cutting solution.