Hi there, I’m Kevin—Sales Manager at Jinan Precise CNC Equipment Co., Ltd. Over the past 5 years, I’ve sat down with hundreds of business owners, fabricators, and hobbyists trying to figure out if a fiber laser cutter is right for them. The first question they always ask? “Is it worth it?”

Today, I’m not here to sell you a machine—I’m here to break down the real pros and cons of fiber laser cutters, compare them to other options (like CO₂ or YAG cutters), and show you why so many of our clients say switching to fiber was one of their best business moves. Let’s dive in.

First: The Pros of Fiber Laser Cutters (Why They’re Taking Over the Industry)

Let’s start with the good stuff—because honestly, fiber laser cutters have changed the game for metal fabrication. Here’s what I hear from clients every week:

1. Unbeatable Precision & Clean Cuts

If you’ve ever struggled with jagged edges, burrs, or parts that don’t fit right, fiber lasers will be a revelation. These machines hit a positioning accuracy of 0.05mm and repeat that accuracy (over and over) at 0.03mm. That’s like cutting a hair into tiny, perfect pieces—no exaggeration.

The beam focuses into a super-tight spot, so the slit (the gap from cutting) is only 0.10–0.20mm wide. No more wasting material on wide cuts, and no more sanding or filing edges to make parts smooth. Most of our clients say they’ve cut their post-processing time by 70%—that’s hours saved every week.

2. Speed That Blows Other Tools Out of the Water

Want to cut metal faster? Fiber lasers clock in at up to 10m/min for cutting and 30m/min for positioning—way faster than plasma cutters, waterjets, or even other lasers. A client of mine in Texas used to take 8 hours to cut 100 metal brackets with their old CO₂ machine; now, with a 3000W fiber laser from us, they do it in 3 hours. That’s more jobs done, more money in their pocket.

3. It’s Gentle on Your Materials (No More Ruined Parts)

Fiber lasers use non-contact cutting—the cutting head never touches the metal. That means no scratches, no dents, and almost zero thermal deformation. I had a client who made custom aluminum parts for airplanes; with their old punch press, 10% of parts got warped from heat. Now? Less than 1% are ruined. For high-value parts, that’s a huge win.

4. Flexible Enough for Any Project

Whether you’re cutting flat sheets, beveled edges, metal tubes, or even 3D shapes (we pair ours with robotic arms for this!), fiber lasers handle it all. Want to switch from cutting 2mm stainless steel signs to 10mm carbon steel pipes? Just tweak the settings in the software—no need to swap out tools or reconfigure the whole machine.

And since it’s dieless cutting? No more spending thousands on molds for custom parts. A small shop in Canada started offering personalized metal art with our fiber laser—they went from 2 custom orders a month to 20, because they didn’t have to charge extra for mold costs.

5. Save Money on Energy & Maintenance (Long-Term)

Here’s where fiber lasers really shine compared to other options: they’re cheap to run. Let’s break it down:

Energy efficiency: Fiber lasers have a 30% photoelectric conversion rate—that’s 3x better than CO₂ lasers. The whole machine uses only 20–30% of the power a similar CO₂ cutter would. One client told me their monthly electricity bill dropped by $400 after switching.

No hidden maintenance costs: CO₂ lasers need expensive working gas and regular lens replacements (think $500–$1,000 every few months). Fiber lasers? No gas, no reflective lenses to adjust or replace. The key components (like the laser source) last up to 100,000 hours—that’s over 10 years of heavy use.

6. Safe & Clean (Your Team Will Thank You)

Let’s be real: metal shops can be messy, noisy places. Fiber lasers change that. They produce less waste, low noise, and no toxic fumes (as long as you use the right ventilation, which we include). All our machines come with built-in dust removal systems, so your team isn’t breathing in metal dust all day. Happier, healthier workers = less turnover.

How Fiber Lasers Stack Up to CO₂ & YAG Cutters

I get it—you might be wondering, “Why not just stick with a CO₂ or YAG cutter I already know?” Let’s compare them head-to-head (I use this chart with clients all the time):

Feature | Fiber Laser Cutter | CO₂ Laser Cutter | YAG Laser Cutter |

Cutting Speed | 2x faster (same power) | Slower | 4–5x slower |

Beam Quality | Finer (smaller focus) | Wider focus | Lowest quality |

Photoelectric Efficiency | 30% | ~10% | ~3% |

Running Costs | 20–30% of CO₂ | High (gas + lenses) | High |

Maintenance | Almost none | Frequent (lenses/gas) | Frequent |

Material Range | Metals only | Metals + non-metals | Metals only |

Price | Mid-range | Highest | Lowest |

The only real downside of fiber vs. CO₂? Fiber lasers only cut metals (aluminum, steel, copper, etc.)—they can’t handle wood, acrylic, or plastic. But if you’re working with metal (which 80% of our clients are), fiber is a no-brainer.

And vs. YAG? YAG cutters are cheaper upfront, but they’re slower, less efficient, and cost more to run long-term. A client once told me they spent $2,000 in YAG maintenance in 6 months—with their fiber laser, they’ve spent $0 in 2 years.

The Cons of Fiber Lasers (Let’s Be Honest)

No machine is perfect, and I want to be transparent about the downsides—so you can make an informed decision:

1. Eye Safety Is Non-Negotiable

Fiber lasers emit intense light that can burn your retina in seconds—even a quick glance without protection can cause permanent damage. That’s why every one of our machines comes with industrial-grade safety goggles, and we train your team on how to use them. No exceptions.

2. Dust & Fumes Need Proper Ventilation

Cutting metal creates fine dust and (sometimes) fumes. If you skip a dust removal system, your team could breathe in harmful particles. But here’s the good news: all our fiber lasers come with built-in dust extractors—no extra cost, no extra setup. Just plug it in, and it works.

3. Fire Risk (Easily Preventable)

We use oxygen for cutting thick metals, which means sparks fly. If you leave flammable materials (like rags or paint cans) near the machine, there’s a fire risk. But again—this is easy to fix. We include fire extinguishers with every machine, and our team walks you through setting up a safe workspace. I’ve never had a client have a fire issue because we prioritize safety from day one.

4. Harmful Fumes from Certain Materials

Some metals (or coatings on metals) can release toxic fumes when cut. For example, cutting galvanized steel releases zinc fumes. But we help you mitigate this: we’ll advise you on which materials are safe, and our machines have fume filters that capture 95% of harmful particles.

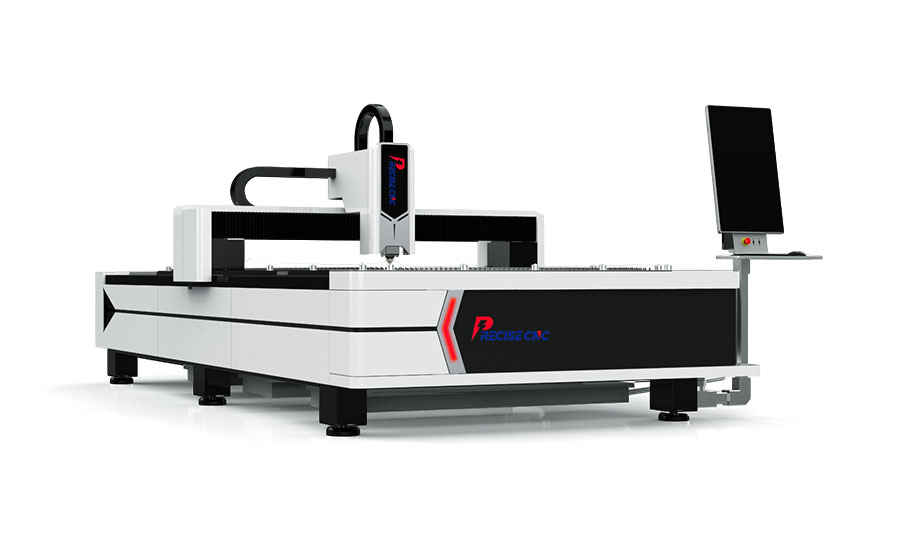

Why Jinan Precise CNC’s Fiber Lasers Are Different

Okay, so you know fiber lasers are great—but why buy one from us? Let me tell you what makes our machines stand out (and why clients keep coming back):

1. We Build for Your Needs (No One-Size-Fits-All)

I don’t sell “standard” machines—I ask questions first. “What’s the thickest metal you cut?” “How many parts do you make a day?” “Do you need tube cutting too?” Then we customize the machine to fit your workflow. A client in Australia needed a machine that could cut both flat sheets and 6-inch pipes—we built them an all-in-one model that saved them $15,000 vs. buying two separate machines.

2. Factory-Direct Pricing (No Middleman Markup)

We’re based in Jinan, China’s CNC manufacturing hub—we build every machine in our own factory. That means no distributors, no extra fees, just you and us. Our 2000W entry-level fiber laser starts at $14,200—hundreds (sometimes thousands) less than big-name brands, with the same quality parts (IPG laser sources, Siemens CNC controls).

3. Support That Doesn’t Stop After You Buy

I’ve had clients call me at 8 PM on a Friday because their machine was down and they had a deadline. We offer 24/7 remote troubleshooting, free tech support for 1 year, and even on-site service if you need it. Last month, a client in Mexico had an issue with their cutting head—we shipped a replacement overnight, and our tech walked their team through installation via video call. No downtime, no stress.

4. We Prove Our Quality (See for Yourself)

Want to know how we build our machines? Check out our About Us page—we have videos of our factory, quality control process, and client testimonials. We even offer virtual factory tours—just ask, and I’ll walk you through our production line. Transparency matters, and we don’t hide anything.

Ready to Find the Right Fiber Laser for You?

If you’re tired of slow, messy cuts, high maintenance costs, or parts that don’t meet your standards, it’s time to talk. Whether you’re a small shop looking for an entry-level machine or a large factory needing a 15,000W industrial cutter, we’ve got you covered.

Here’s how to get started:

Head to our Contact Us page

Drop me a message with:

What materials you cut (steel, aluminum, etc.)

The thickness of the material

How many parts you make per week

I’ll send you a free, personalized quote (no obligation) and answer any questions you have—even the ones about safety, maintenance, or shipping.

I’m not here to pressure you—I’m here to help you find a machine that makes your business faster, more efficient, and more profitable. Let’s build something great together.