In the rapidly evolving landscape of metal fabrication, the demand for precision, efficiency, and versatility is higher than ever. As we look towards 2025, sheet metal laser cutting technology continues to lead the way, offering unparalleled capabilities for various industries. This comprehensive guide will delve into what makes a laser cutter stand out in the market, highlighting key features and benefits, and guiding you towards making an informed decision for your business. We will also introduce Jinan Precise CNC Equipment Co., Ltd. and its commitment to delivering high-quality laser cutting solutions.

Why Choose Sheet Metal Laser Cutting in 2025?

Sheet metal laser cutting has revolutionized the manufacturing industry, offering significant advantages over traditional cutting methods. The technology has evolved dramatically, making it the preferred choice for businesses seeking precision and efficiency. Here are the primary benefits that make laser cutting the best choice for metal fabrication:

Unmatched Precision and Accuracy: Modern fiber laser cutting machines can achieve incredibly tight tolerances, producing intricate designs and precise cuts that are difficult, if not impossible, with conventional tools. This precision leads to higher quality finished products and reduced material waste, directly impacting your bottom line.

High Speed and Efficiency: Fiber laser cutting machines are renowned for their rapid processing speeds, significantly reducing production times and increasing throughput. This efficiency translates directly into cost savings and improved productivity, making them ideal for both small-scale operations and large industrial applications.

Versatility Across Materials: Modern laser cutters can process a wide array of metal materials, including carbon steel, stainless steel, aluminum, brass, copper, and titanium. This versatility accommodates diverse manufacturing needs, making a single machine capable of handling multiple projects and material types.

Minimal Material Waste: The focused laser beam allows for optimal material utilization, minimizing scrap and maximizing profitability. The non-contact nature of laser cutting also prevents material deformation, ensuring consistent quality across all cuts.

Superior Edge Quality: Laser-cut parts boast smooth, clean, and burr-free edges, often eliminating the need for secondary finishing processes. This saves both time and labor costs while ensuring consistent quality standards.

Ability to Handle Complex Geometries: From simple straight lines to highly complex and intricate patterns, laser cutting machines can execute a vast range of designs with ease and consistency. This capability opens up new possibilities for innovative product designs and manufacturing approaches.

When investing in a sheet metal laser cutter, several factors contribute to its overall performance and value. Understanding these features will help you make an informed decision that aligns with your business needs:

Laser Power and Performance: The power of the laser, measured in watts, directly impacts cutting speed and the thickness of materials it can process. High-power fiber lasers ranging from 1000W to 6000W or higher offer faster cutting speeds and greater material versatility. Consider your typical material thickness and production volume when selecting the appropriate power level.

Machine Bed Size and Working Area: The size of the working area determines the maximum dimensions of the sheet metal you can process. Common sizes include 4x8 feet, 5x10 feet, and larger formats. Choose a size that aligns with your production requirements while considering future expansion needs.

Advanced Automation Features: Modern laser cutting systems incorporate sophisticated automation features such as automatic loading/unloading systems, intelligent nesting software, and automatic gas and lubrication systems. These features significantly enhance efficiency and reduce manual labor requirements.

Control System and Software: A user-friendly and robust control system is crucial for seamless operation, precise control, and efficient job management. Look for systems that offer intuitive interfaces, advanced programming capabilities, and compatibility with popular CAD/CAM software.

Safety Features and Compliance: Enclosed designs, safety interlocks, and protective measures are essential for operator safety and compliance with industry standards. Modern machines should include comprehensive safety systems that protect both operators and equipment.

Build Quality and Durability: The construction quality of the machine frame, components, and overall design directly impacts long-term reliability and performance. Look for machines built with high-quality materials and precision engineering.

Types of Sheet Metal Laser Cutting Machines Available

Understanding the different types of laser cutting machines available can help you choose the best option for your specific needs:

Standard Sheet Metal Fiber Laser Cutting Machines: These are the most common type, designed for cutting flat sheet metal with high precision and speed. They offer excellent value for money and are suitable for a wide range of applications.

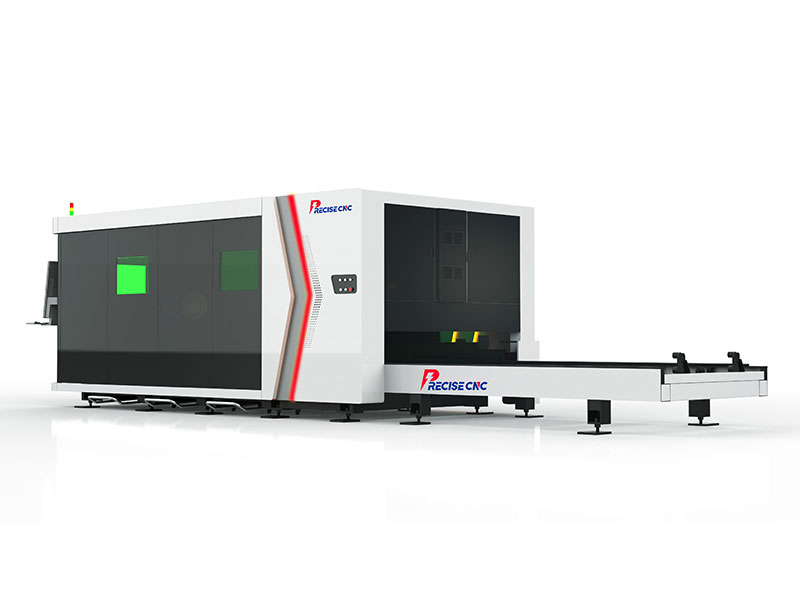

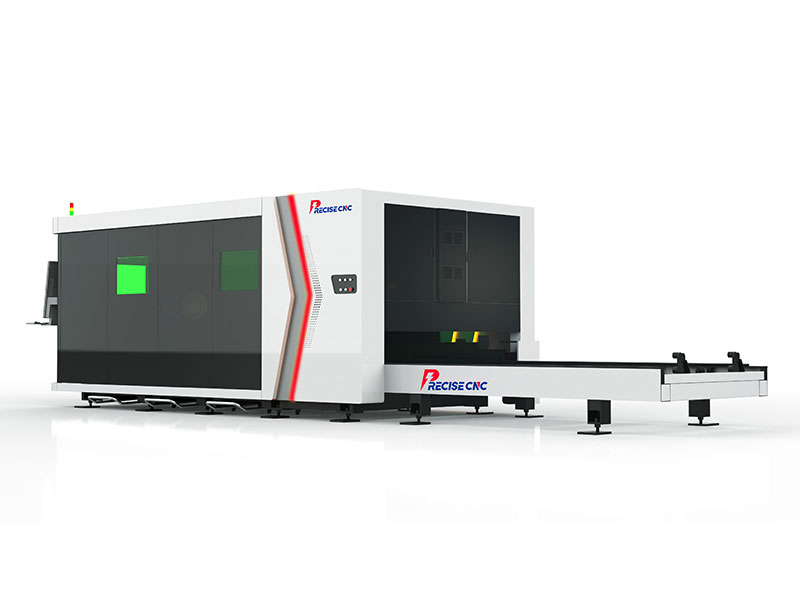

Enclosure Protection Metal Fiber Laser Cutting Machines: These machines feature fully enclosed designs for enhanced safety and environmental control. They're ideal for operations requiring strict safety protocols or working with hazardous materials.

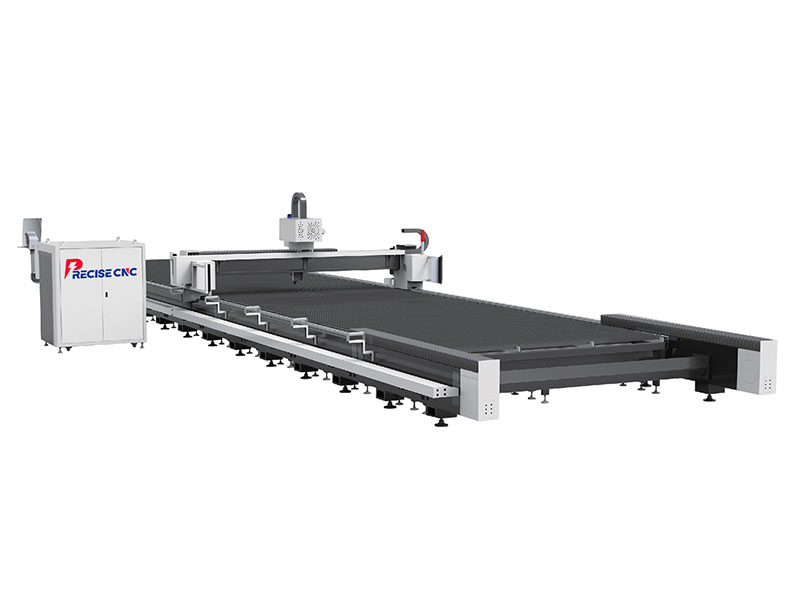

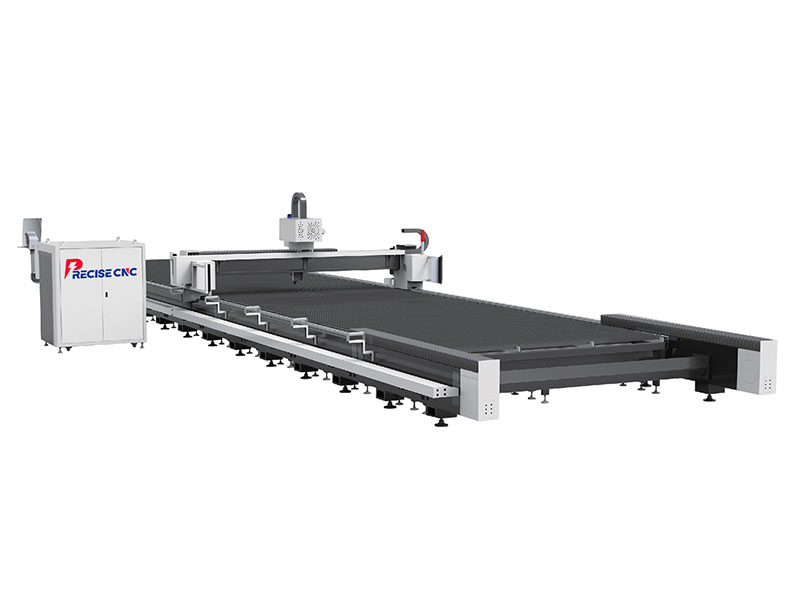

Ground Rail Metal Fiber Laser Cutting Machines: Designed for processing larger sheets, these machines feature extended working areas and robust construction to handle heavy-duty applications.

Precision Metal Fiber Laser Cutting Machines: These specialized machines offer enhanced precision capabilities for applications requiring extremely tight tolerances and superior edge quality.

Steel Coil Metal Fiber Laser Cutting Machines: Designed specifically for processing steel coils, these machines offer automated feeding and cutting capabilities for high-volume production environments.

Industry Applications and Benefits

Sheet metal laser cutting technology serves numerous industries, each benefiting from its unique capabilities:

Automotive Industry: Precision cutting of body panels, chassis components, and decorative elements with consistent quality and tight tolerances.

Aerospace Industry: Processing of lightweight materials like aluminum and titanium for aircraft components requiring exceptional precision and reliability.

Construction and Architecture: Cutting of structural steel, decorative panels, and custom architectural elements with complex geometries.

Electronics and Technology: Precision cutting of enclosures, heat sinks, and component parts for electronic devices and equipment.

Medical Device Manufacturing: Production of surgical instruments, implants, and medical equipment components requiring biocompatible materials and precise specifications.

Cost Considerations and ROI

When evaluating the best laser cutter for sale, it's important to consider both initial investment and long-term return on investment:

Initial Investment: Fiber laser cutting machines typically range from $30,000 to $600,000 depending on power, size, and features. Entry-level machines suitable for small businesses start around $15,000, while high-end industrial systems can exceed $1,000,000.

Operating Costs: Consider ongoing expenses such as electricity, consumables (gases, lenses, nozzles), maintenance, and operator training. Fiber lasers generally offer lower operating costs compared to CO2 lasers due to higher efficiency and lower maintenance requirements.

Productivity Gains: The speed and precision of laser cutting can significantly increase productivity, reduce labor costs, and improve product quality, leading to faster ROI realization.

Material Savings: Reduced waste and improved material utilization can result in substantial cost savings over time, especially for high-volume operations.

Jinan Precise CNC Equipment Co., Ltd.: Your Partner in Laser Cutting Excellence

Jinan Precise CNC Equipment Co., Ltd. stands as a leading provider of high-quality laser cutting solutions, committed to delivering cutting-edge technology and exceptional service. Our comprehensive range of Sheet Metal Laser Cutting Machines is designed to meet the rigorous demands of modern manufacturing, offering unparalleled value and performance.

Advanced Fiber Laser Technology: We integrate the latest fiber laser technology to ensure superior cutting performance, speed, and precision. Our machines utilize high-quality laser sources from renowned manufacturers, ensuring consistent performance and long service life.

Robust Construction and Engineering: Our machines are built with durability and stability in mind, featuring heavy-duty frames, precision linear guides, and high-quality components. This robust construction ensures long-term reliability and consistent results even in demanding industrial environments.

Customizable Solutions for Every Need: We understand that every business has unique requirements. Our team works closely with customers to provide tailored solutions that fit specific applications, production volumes, and budget constraints. From entry-level machines for small businesses to high-power industrial systems, we have options for every need.

Comprehensive Support and Service: At Jinan Precise CNC, customer satisfaction is our top priority. We provide extensive pre-sales consultation to help you select the right machine, professional installation and commissioning, thorough operator training, and responsive after-sales technical support to ensure your continued success.

Quality Assurance and Reliability: We adhere to stringent quality control standards throughout the manufacturing process, from component selection to final testing. Each machine undergoes comprehensive quality checks to guarantee optimal performance and reliability.

Competitive Pricing and Value: We offer competitive pricing without compromising on quality, ensuring that our customers receive exceptional value for their investment. Our direct manufacturing approach allows us to provide cost-effective solutions while maintaining high standards.

Technical Specifications and Performance

Our sheet metal laser cutting machines offer impressive technical specifications that deliver superior performance:

Power Range: Available in power options from 1000W to 6000W and beyond, suitable for cutting various material thicknesses and types.

Cutting Speed: High-speed cutting capabilities with speeds up to 100 meters per minute on thin materials, significantly reducing production time.

Positioning Accuracy: Precision positioning with accuracy up to ±0.03mm, ensuring consistent quality across all cuts.

Material Compatibility: Capable of processing carbon steel, stainless steel, aluminum, brass, copper, titanium, and other metal materials with thicknesses ranging from 0.5mm to 25mm or more, depending on power and material type.

Working Area Options: Multiple bed size options available, from compact 1300x900mm units to large-format 6000x2000mm systems and beyond.

Maintenance and Support

Proper maintenance is crucial for optimal performance and longevity of your laser cutting equipment:

Preventive Maintenance: Regular maintenance schedules help prevent unexpected downtime and ensure consistent performance. Our machines are designed for easy maintenance with accessible components and clear maintenance procedures.

Technical Support: Our experienced technical support team provides prompt assistance for troubleshooting, maintenance guidance, and operational questions. We offer both remote support and on-site service when needed.

Spare Parts Availability: We maintain comprehensive spare parts inventory to ensure quick availability of replacement components, minimizing downtime and maintaining productivity.

Training Programs: Comprehensive operator training programs ensure that your team can operate the equipment safely and efficiently, maximizing productivity and equipment lifespan.

Future Trends in Laser Cutting Technology

As we look toward 2025 and beyond, several trends are shaping the future of laser cutting technology:

Increased Automation: Integration of artificial intelligence and machine learning for automated parameter optimization, predictive maintenance, and quality control.

Enhanced Connectivity: IoT integration for remote monitoring, data analytics, and predictive maintenance capabilities.

Improved Energy Efficiency: Continued development of more efficient laser sources and power management systems to reduce operating costs and environmental impact.

Advanced Materials Processing: Expanded capabilities for processing new materials and alloys, including advanced composites and specialized metals.

Making the Right Choice for Your Business

Selecting the best sheet metal laser cutter for sale requires careful consideration of your specific needs, budget, and growth plans:

Assess Your Requirements: Evaluate your typical material types, thicknesses, production volumes, and quality requirements to determine the appropriate machine specifications.

Consider Future Growth: Choose a machine that can accommodate your current needs while providing room for future expansion and increased production demands.

Evaluate Total Cost of Ownership: Consider not just the initial purchase price, but also operating costs, maintenance requirements, and potential productivity gains.

Partner with a Reliable Supplier: Choose a supplier with a proven track record, comprehensive support services, and commitment to customer success.

Conclusion

As we advance into 2025, investing in a high-quality sheet metal laser cutter represents a strategic decision that can significantly enhance your manufacturing capabilities, improve efficiency, and drive profitability. The technology continues to evolve, offering increasingly sophisticated features and capabilities that enable businesses to stay competitive in today's demanding market.

Jinan Precise CNC Equipment Co., Ltd. stands ready to be your trusted partner in this journey, offering advanced laser cutting solutions backed by unparalleled expertise, comprehensive support, and unwavering commitment to customer success. Our range of sheet metal laser cutting machines combines cutting-edge technology with robust construction and competitive pricing to deliver exceptional value for businesses of all sizes.

Whether you're a small fabrication shop looking to expand your capabilities or a large industrial manufacturer seeking to optimize your production processes, we have the expertise and equipment to meet your needs. Our commitment to quality, innovation, and customer satisfaction ensures that your investment in our technology will deliver long-term value and success.

Ready to Transform Your Metal Fabrication Operations?

Don't let outdated cutting methods hold your business back. Discover how Jinan Precise CNC Equipment Co., Ltd. can transform your sheet metal processing capabilities with our state-of-the-art laser cutting machines.

Contact us today for a personalized consultation where our experts will assess your specific needs and recommend the best sheet metal laser cutter for your applications. We'll provide detailed specifications, pricing information, and demonstrate how our technology can improve your productivity, quality, and profitability.

Take the first step toward revolutionizing your manufacturing processes. Let us help you achieve precision, speed, and efficiency that will set your business apart from the competition.

Contact Information:

Request your free quote today and discover why businesses worldwide trust Jinan Precise CNC Equipment Co., Ltd. for their laser cutting needs. Our team is ready to help you find the perfect solution for your metal fabrication requirements.